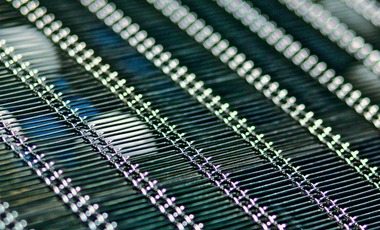

Industrial wire screens - processing any challenge

Under the motto “Time to chain”, the HAVER & BOECKER Wire Weaving and Machinery Divisions are presenting their product lines at POWTECH 2014. Since early this year the Oelde-Germany based company has touted the linking of premium technologies to form complete plants. In addition to its new packing systems, HAVER & BOECKER will also be showcasing the technological components of its subsidiary companies BEHN + BATES and HAVER ENGINEERING.

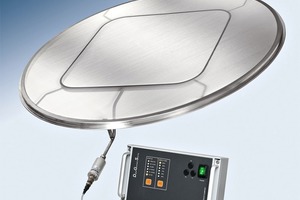

Ultrasonic screens in all variations – safety in critical areas as well

For years HAVER & BOECKER is collaborating with ARTECH Ultrasonic Systems AG, an international leader in ultrasound technology, to provide custom-made ultrasonic screening systems with innovative frequency variation. This type of screening systems provides for more efficient screening because it improves screen throughput, helps to break down agglomerates, reduces the amount of oversize particles and ensures a long-term cleaning effect. Ultrasonic screening solutions by HAVER & BOECKER can be used for cut sizes of approx. 1000 µm to 25 µm.

Besides the well-known use on vibrating screening machines, HAVER & BOECKER exhibits ultrasonic technology for gyratory screening machines during POWTECH 2014. Also showcased will be new features of the ultrasonic system: pulsating and interval sieving programs as well as new safety features increase screening efficiency and operational reliability significantly.

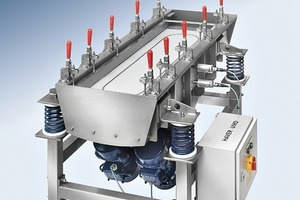

HAVER screening machine UMD – great performance on a small footprint

For screening small production volumes and small single batches and for applications on laboratory and pilot plant scale, HAVER & BOECKER offers the sleek screening machine HAVER UMD. This linear vibrating screen is suitable for a large variety of bulk materials such as sand, gravel, ore or coal, as well as for sensitive or aggressive products. The screen frames can also be equipped with ball trays or ARTECH ultrasonics to allow for implementation of ultra-fine cut sizes and good self-cleaning of the wire cloth. These screening aids furthermore improve the screening results and increase the throughput rate. The size of the machine and its design, which allows for batch and for continuous operation, make it particularly suitable for use in smaller industrial applications.

Traditional particle analysis

Based on more than 125 years of experience in wire fabric technology HAVER & BOECKER provides innovative systems which continue to set new standards in functionality, precision and reliability. Standard-compliant test sieves for hand sieving, conventional sieving, dry or wet screening are offered for aperture sizes of 5 microns to 125 mm. The characteristic feature of the electromagnetic 3D Test Sieve Shakers for dry and wet sieving is the self-readjusting amplitude. The TYLER-Ro Tap® by the American subsidiary of HAVER & BOECKER, W.S.TYLER, has been popular for decades within the abrasive and mining industry with the simulation of hand sieving by a circular and tapping motion. The HAVER UWL 400 is designed for coarse and heavy samples with two rotary current unbalanced motors. The new HAVER CSA 5.0 software quickly enables computerized evaluation of sieve analyses.

Photo-optical particle analyses – HAVER CPA

The HAVER CPA measuring process enables the analysis of particle sizes and particle shapes of dry and free-falling particles of bulk materials in a measuring range from 10 µm up to 400 mm. As standardized laboratory units, customized industrial solutions or in combination with HAVER peripherals for systems to be made to measure: the HAVER CPA analyses gravel, sand, granulates, wood chippings, pharmaceutical products or foodstuffs in real time. A high-resolution digital line scan camera scans the particles against the background of an LED light source with a recording frequency of up to 28 000 line scans per second. The scanned lines are combined to form an endless data record and the shadow projections of the particles are evaluated simultaneously to the measuring process. In addition to our standard systems HAVER & BOECKER also develops special solutions for special tasks.

Sample dividers – conventionally and by rotation

HAVER Sample Reducers produce representative sample quantities. The HAVER Sample Splitter forms two subsamples by means of alternately arranged dividers in the splitter head. The HAVER RPT Rotating Sample Reducer produces 8, 10 or 30 small samples of solids and suspensions and is combined with high-accuracy analytical measuring instruments. It is used in research, development and process monitoring laboratories. HAVER RPT combines three dividing methods in one unit and provides the best possible sample reducing available today. The rotation and number of dividing conditions enable variable dividing conditions to be achieved up to 3000 dividing steps per minute. The HAVER RPT rotating cone sample reducer thus achieves an accuracy of 99.9 %. Even heavy flowing materials such as cement or limestone can be divided with high accuracy in this way.

The ROTO-PACKER® for small bags enables the filling of powder-products into compact PE bags for the first time

With the new small-bag packing machine, HAVER & BOECKER will be featuring a worldwide innovation. The new ROTO-PACKER® is based on the proven ADAMS® technology and fills powder-type bulk products into compact PE bags for the first time, reaching a speed of up to 600 bags per hour and featuring a stepless bag weight selection of 1–10 kg. Filling into bags made from a film tube or pre-made bags is now possible. Using an additional module, the customer may also form the bag from a flat film within the ROTO-PACKER® system.

The bags are sealed air-tight and are impermeable to the weather. They are clean, compact and provide for an attractive appearance. The customer saves costs in packaging, storage, and from fewer complaints.

Pneumatikpacker using a modular system

BEHN + BATES, the specialist for filling food and feedstuffs, features its modular-system Pneumatikpacker, which means it can be adapted rapidly to suit customer demands. The BEHN + BATES Pneumatikpacker has been proven over many years and remains the optimum packing system for filling all free-flowing, flour, powder, and grainy-type products, e.g. starch, flour, cocoa powder, protein, sugar, etc. into valve bags. Depending on the product and filled weight, hourly filling speeds of up to 300 bags per hour for bag weights of 10–50 kg are possible.

Pelletizing plates for mechanical processing technology laboratories

One premiere is the introduction of the HAVER SC 500 pelletizing plate. HAVER ENGINEERING developed it especially for the requirements of mechanical processing technology laboratories. With a diameter of 500 mm, small-scale trials on agglomeration in continuous operation are possible for the first time without the need for large material quantities. As a result representative findings can be gained and directly applied to the production process, e.g. the effectiveness of binding agents and additives.

Hall 1, Stand 533

//www.haverboecker.com" target="_blank" >www.haverboecker.com:www.haverboecker.com