Higher capacities and safer operation

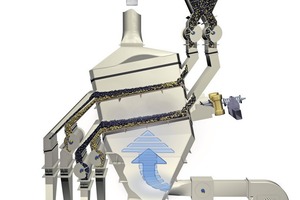

In the early 2000s allmineral introduced the allair® jig which is working completely dry with air only to the coal industry. Since then about 80 allair® jigs have been supplied for coal preparation plants in the U.S., India, Colombia, Spain and Ukraine. Capacities of these jigs are – depending on the feed size – between 60 and 30 t/h. The capacities per jig can be doubled by using the recently developed allair® type MP fitted with two jigging decks in one unit reaching capacities of up to 120 t/h. The combination of residual energy (air pressure and volume) from the lower deck is used with an additional small airflow from the main fan (via bypass) for stratification of the material on the upper deck (Fig. 1).

The big advantage of the design of the allair® jig type MP is that – although capacities have been doubled – the footprint of the jig plant remains the same and jigging air requirement is only marginally increased compared to the single deck units. The first allair® type MP plant has been commissioned successfully earlier this year in India (Fig. 2) where 35 allair® jig units are in operation already.

No more clogging

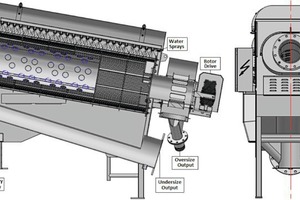

Another new development allmineral is introducing to the market currently is related to the gaustec® wet high intensity magnetic separators (WHIMS). While over the last years the increase of feed capacities was in the focus of their R&D work, which resulted in feed capacities of up to 1400 t/h per unit, safer and trouble-free operation was the goal of gaustec’s latest development, the gaustec® NoBLOCK screen. This NoBLOCK screen sits upstream of the WHIMS and avoids the known, but so far unsolved issue of clogging of matrix boxes by oversize materials. Such clogging results in less efficient separation, capacity reduction and finally plant downtime for cleaning the matrix boxes which can take days depending on the number of matrix boxes installed.

Even though standard screens installed upstream of the WHIMS provide some protection, its use has proven that it is a good but not 100 % safe solution. Wear and shape of the PU panels typically used for these screens do not prevent oversize particles ending up in the screen underflow, at least to a certain extent. Over time any oversized particles in the WHIMS feed create the above mentioned issues. In order to achieve the best protection and more reliable operation a new concept had to be developed. Such protection screen had to be designed to ensure that once a particle has passed it, it should also pass through the matrix box openings. The solution was to use screen panels made out of the same steel used for matrix boxes applying the same shape of the matrix box gap in order to prevent oversized particles to enter the process.

This goal was achieved by cutting slices of proper thickness from the grooved plate matrix boxes. These screen panels are curved to an extend suitable to provide a path with an opening beginning at the standard matrix box gap and widening gradually towards the output. This geometry allows for a loose path for the outgoing undersized particles (Fig. 2).

The slurry feed flows inside the rotor and is screened by the matrix screen panels. The oversized particles travel inside the rotor at a speed proportional to the rotor revolutions. Transport is facilitated by the rotor’s 10 degrees slope. The oversized particles are discharged at the end of the rotor through the oversize output. All other particles suitably sized for the WHIMS process pass through the screen gaps to the undersize output discharge. To increase the protection grade the gap openings of the screen panels are smaller than the gaps of the matrix boxes installed in the WHIMS. Water jets mounted above the rotor remove the particles which got stuck in the gaps. These water jets keep the rotor clean in order to perform its screening function correctly. Furthermore there is an emergency overflow output under the NoBLOCK Screen in case slurry in excess of the rated capacity flow is fed (Fig. 4).

$(LEhttp://