Hellenic starts up rotoform lines

Sandvik has completed commissioning of an end-to-end sulphur solidification and handling system at Hellenic Petroleum S.A.’s refinery in Elefsis, marking an important milestone in a larger environmental upgrading of this major facility. Sandvik Process Systems has delivered a solidification solution based on four of its Rotoform® granulation systems, each with a capacity of approx. 300 t/day, while sister company Sandvik Mining and Construction has installed solid sulphur handling facilities, including stacking, storage, reclaiming and ship-loading equipment. The project continues a relationship that extends back to the mid-1980s when Sandvik first installed sulphur granulation lines at Hellenic Petroleum’s refinery in Aspropyrgos.

The objective of the overall refinery upgrade is to give the Greek energy giant the ability to handle different kinds of crude and enable production of ultra low sulphur fuels. Other goals include a significant reduction in emissions together with efficiency enhancements and improved safety conditions. Sandvik’s Rotoform system offers a number of process benefits but for Hellenic it is the inherent cleanliness that is one of its key advantages.

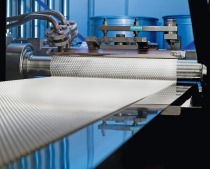

Solidification of the sulphur extracted during refining is carried out on Sandvik’s Rotoform units. These consist of a heated, cylindrical stator and a perforated rotating shell that turns concentrically around the stator, depositing sulphur drops across a continuously running steel belt. The speed of the Rotoform is synchronised with the speed of the belt, ensuring that drops are deposited accurately, consistently and without deformation.

The belt is cooled by water sprayed on the underside and the resulting heat transfer results in rapid solidification of the product. The fact that there is no contact between the molten sulphur and the cooling water means there is no risk of cross contamination and the water can be recycled within the system, again and again.

The sulphur droplets are then discharged as solid, hemispherically-shaped pastilles at the end of the cooling system, and conveyed outside the solidification building to the covered stockpile area. As the refinery is located close to a densely populated area, these facilities have been designed to minimise any impact on the environment. This includes enclosed storage, enclosed conveyor galleries, dust suppression at loading points and the use of telescopic chutes in shiploaders.

The stockpile feeding system uses a belt conveyor with a capacity of 33,5 t/h to feed a distribution system at a height of approximately 20 m. The stockpile has the capacity to house around a month‘s sulphur production, approximately 10 300 metric tons. Two shiploaders have been installed, each fed by a 70 m transfer belt and delivering a combined maximum loading capacity of 70 t/h.