Sandvik Process Systems

Drawing on its many years of experience and know-how in the pastillation of a wide range of molten materials, Sandvik Process Systems has further developed its Rotoform® technology. As a successor to the first Rotoform generation and the two following RF3000 generations, the Rotoform 4G has been launched as the fourth generation of this system. With the Rotoform 4G, Sandvik’s Fellbach-based subsidiary is bringing a completely new model to the market and will present it at POWTECH 2013.

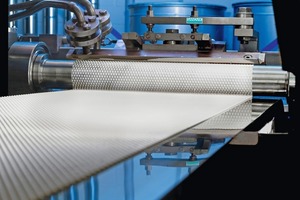

With the combination of Rotoform® and Sandvik steel belt cooler, Sandvik’s Rotoform® principle presents an outstanding, environmentally friendly process for the production of very uniform, dimensionally stable and dust-free pastilles. More than 1600 Sandvik Rotoform plants are now in use worldwide, affirming the resounding success of this system. Different granulation applications are realized continuously and yet flexibly at low cost day after day and shift after shift (Fig.). A processing plant based on the Rotoform® principle is generally designed as an integrated system.

The core element of the system is the Rotoform®, consisting of a fully heated fixed stator and a perforated, rotating cylinder (outer shell), The liquid product is fed from the side (with a volumetric pump) and released in droplets via the outer shell that rotates concentrically around the stator over the entire useful width of the steel belt. The heat released during solidification is given off via the steel belt to the cooling water, which is sprayed against the underside of the belt by means of a spray system. Thanks to the highly efficient heat transfer of the stainless steel belt and the effective cooling, the melt droplets solidify rapidly on the stainless steel belt and are taken off at the end of the Sandvik steel belt cooler as solid, dry, free-flowing and dust-free pastilles – ideal for the transport, storage and any required further processing.

With this very flexible but at the same time very rugged high-tech process, melts to a feed temperature of 320 °C and a viscosity of around 30 000 mPas can be processed. Depending on the product, pastilles can be produced in the size range of around 1.5 to 30 mm. The diameter of the pastilles can be changed by means of simple adjustment of parameters during ongoing operation, or – if bigger changes to the diameter are required – with a fast change of the Rotoform® outer shell. Another advantage of the process is its pronounced environment friendliness. With the strict separation of cooling medium and product with the sealed steel belt, neither product pastilles nor the cooling water are contaminated. Thanks to the rapid cooling and solidification – in the range of a few seconds to several minutes – the product can absorb only extremely little oxygen. Generally, the emission of gases and/or vapours is minimal or very low.

The Rotoform® 4G is the new standard model and can be used very flexibly, e.g. for pastillation of such wide-ranging products as hot melt adhesives, resins, waxes, fatty alcohols, anti oxidants or sulphur, etc.

Sandvik has the know-how, a stable financial background as well as a powerful global organization to supply integrated turnkey plants including loading, unloading and storage equipment and the associated state-of-the-art control systems. The company has a number of test centres worldwide in which the Rotoform® technology can be tested with customer products and demonstrated. In addition, several units are available for tests and pilot scale production in customer plants and laboratories.

Hall 4; Stand 107