Comparative studies of methods for quantitative microstructural analysis in mineral processing

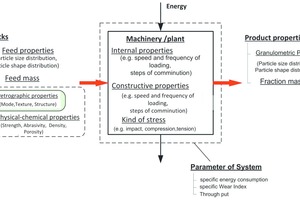

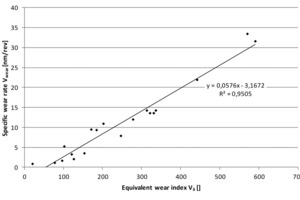

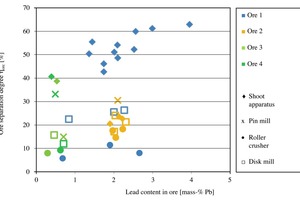

Summary: In different fields, quantitative microstructural analysis (QMA) has become established as a method for characterizing materials and raw materials. Many studies show that the microstructure of the raw materials significantly influences the product properties (e.g. product shape, particle size distribution), comminution energy and wear. For this reason, it is necessary not only to use qualitative data, but increasingly to collect and utilize quantitative data for optimization of mineral processing. This article provides an overview of selected processes and methods of QMA in geology, petrography, mineralogy and processing of mineral resources.

1 Introduction

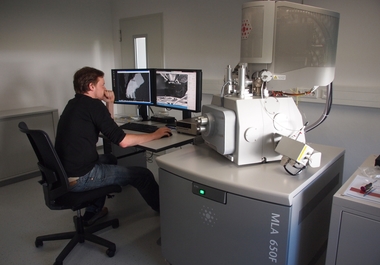

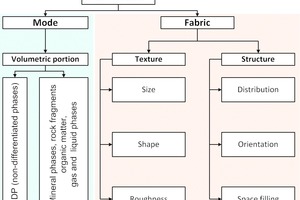

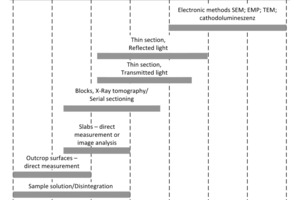

For the quantitative microstructural analysis of mineral resources, various analytical methods are available, For the quantification of microstructures, different values are required that characterize their modes, structure and texture. These methods differ with regard to preparation of samples for analysis as well as their resolution and range of application. With combinations of different methods, the range of application for the analysis systems is widened as not every analytical method allows the capture of all quantitative microstructural parameters.

The...

![3 Bilder von Lichtmikroskopie (links), REM (Mitte [19]) und Computertomographie (rechts) • Images of light microscopy (left), SEM (centre [19]) and computer tomography (right)](https://www.at-minerals.com/imgs/1/3/3/2/2/4/7/tok_4c67eab652a7286fd7bf6694aff86ff9/w300_h200_x600_y197_03_Abb._3-fa11f64f0c2d823b.jpeg)

![4 Flussdiagramm zur Erzeugung von segmentierten, klassifizierten Bildern für die Bildanalyse [17] • Flow chart for making segmented classified images for image analysis [17]](https://www.at-minerals.com/imgs/1/3/3/2/2/4/7/tok_cdb63c8e0e00e6566fd76d60d566ca7d/w300_h200_x600_y173_04_Abb._4_korr-2f6bd86c0763c796.jpeg)

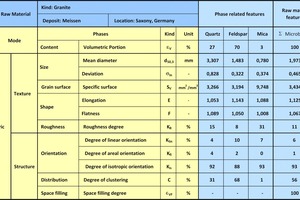

![6 Datenblatt Gesteinscharakteristika [35] • Datasheet on rock characteristics [35]](https://www.at-minerals.com/imgs/1/3/3/2/2/4/7/tok_0c1ccd9581f0bd57dd30a5907aa6214b/w300_h200_x600_y470_06_Abb._6_korr-024a2f609acc978e.jpeg)

![10 Signalarten der Elektronen [29] • Electron signal types [29]](https://www.at-minerals.com/imgs/1/3/3/2/2/4/7/tok_09af68b27dab38a248dc47fada8b87ff/w300_h200_x600_y391_10_Abb.10-a2d9870b8de962d9.jpeg)

![11 BSE-Bild (links – a) [17] und Topographiebild von SE (rechts – b) [42] • BSE image (left – a) [17] and topography image of SE (right – b) [42]](https://www.at-minerals.com/imgs/1/3/3/2/2/4/7/tok_1449c568181c716b6d611ff0eddb5c10/w300_h200_x600_y298_11_Abb_11-a6bfdae88f0e0b0c.jpeg)

![12 EDX-Bild (links – a) [12] und Kathodolumineszenzbild (rechts – b) [39] • EDX image (left – a) [12] and cathodoluminescence image (right – b) [39]](https://www.at-minerals.com/imgs/1/3/3/2/2/4/7/tok_db4d34c8a259a73ddf3e0ad6fc68fe60/w300_h200_x600_y219_12_Abb_12-24f9466857494776.jpeg)

![13 Kikuchi-Linien (links – a) [10] und EBSD-Bild (rechts – b) [10] • Kikuchi lines (left – a) [10] and EBSD image (right – b) [10]](https://www.at-minerals.com/imgs/1/3/3/2/2/4/7/tok_59d7988d0810702a293aa72db7f71dbc/w300_h200_x520_y254_13_Abb_13-f4fc2e771ef835c7.jpeg)

![14 Lichtmikroskopie (HF links – a) und BSE-Bild (rechts – b) [12] • Light microscopy (HF left – a) and BSE image (right – b) [12]](https://www.at-minerals.com/imgs/1/3/3/2/2/4/7/tok_70e6885faddf102c57c0001498e3a6d7/w300_h200_x600_y203_14_Abb_14-0729457182fb8e65.jpeg)

![15 Scannen von Bohrkernen [26] • Core scanning [26]](https://www.at-minerals.com/imgs/1/3/3/2/2/4/7/tok_ab429968d6f9a98d902f077f54338dc7/w300_h200_x600_y164_15_Abb.15-4ebdf5e706644a02.jpeg)