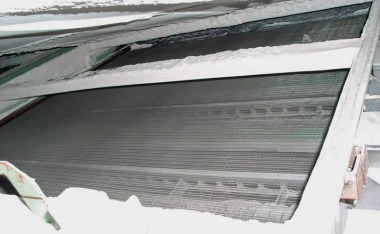

RHEWUM screen for crushed glass

Specific feature of the RHEWUM Magnetic Screen is the very fine screen cut specified by Colorobbia S.p.A., Italy. A crushed glass mixture (Fig.) of 0.08-3.0 mm has to be screened to two fractions of 80-150 µm and 150-300 µm. Accepted amount of outsize particles of each fraction is max. 3 % at a capacity of 20 t/h. Several trials have shown that these exact screening can only be done by use of a screening machine with electromagnetic drives type RHEWUM WA. In this project a screening machine type WA 175 x 269/3 with the new developed directly screwed DWA magnetic heads was chosen. They are controlled by the also new developed control functional block type WA4 which reduces sound emission by the principle of counter sound. To reduce wear all parts of the machine which are in contact with the product are equipped with wear protection. The design of the plant was made by Gruppo Minerali and delivery and assembling was done by company La Toscana Impianti.