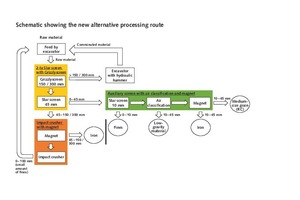

Screening and crushing instead of crushing and screening

The new grizzlyscreen supplied by Backers enables a new, alternative processing of C&D material, mineral soils and rocks with clay stuck to them. The rotating rollers, which are very firmly fixed at one end, ensure the continuous removal of any large particles. The fines 0 – 150/300 mm are loosened up. From the hopper, the fines are fed on the ascending 6.7-m-long screen deck, where at, for example, 45 mm is screened with high efficiency. The cleaned 45 – 150/300 mm size is then transferred directly to a new impact crusher.

This combination has advantages, especially for soil recycling, but also for the recycling of C&D material. Grizzly screen, star screen and magnet offer the crusher protection against relatively large stones, iron and cohesive soils. The fines 0 – 45 mm (soils and similar) can be then be processed separately from the coarse material. High throughput is achieved with simultaneously reduced wear and operating costs. As everything is crushed relatively coarse, the dust content is substantially reduced. Further advantages are that stones are separated from coherent soils and only crushed (into cubic particles) afterwards. The finished products are separated optimally and with high efficiency.

The material flow 0 – 45 mm is fed to an auxiliary screen with which cleaning is performed at 10 mm. At the end of the fine screen, low-gravity particles are extracted by an air classifier and any iron is removed on the downstream belt conveyor.

//www.backers.de" target="_blank" >www.backers.de:www.backers.de