Simple real-time monitoring of electric motors

09.08.2018

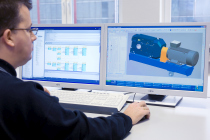

The WEG Motor Scan enables real-time monitoring based on read-out operating data

The WEG Motor Scan enables real-time monitoring based on read-out operating data

Quelle/Source: WEG

The WEG Motor Scan is a solution developed by WEG for the remote performance monitoring of electric motors. WEG Motor Scan enables real-time monitoring of WEG electric motors in a cost-efficient way by means of an intelligent device App available for both Android and iOS. With this App, it is possible to monitor any number of motors. Based on the read-out operating data, plant operators and maintenance staff are able to plan preventive or predictive maintenance, which contributes to a longer service life of the motors and higher plant availability.

Wilmar Henning, Managing Director of WEG Deutschland, comments: “In the field of Industry 4.0 and networked drive technology, WEG focusses on technologies that provide users direct added value at reasonable costs. The WEG Motor Scan meets these requirements exactly. The real-time monitoring enables our solution to prevent problems and failures even before it comes to the crunch. Thus, users can reduce costs, improve the profitability of their machines and plants and use their resources more efficiently.”

With dimensions of 44 x 38 x 25 mm, the WEG Motor Scan can be installed as retrofit in IEC sizes of 6 to 450. Besides surface temperature and service life, it also measures the vibrations of the motor, which is possible by means of 3-axis vibration measurement up to 3 kHz. At a later time, the WEG Motor Scan will determine and log the values of rotational speed, start/stop time, load and efficiency.

The Condition Monitoring solution complies with protection class IP66 and is suitable for most diverse industrial applications. The WEG IoT platform provides comprehensive analysis tools for field diagnosis and allows the configuring of warnings in case certain values are exceeded. Maintenance staff can thus retrieve real-time data regarding the current performance of the electric motor from everywhere via tablet or smartphone to directly analyze them via App or Web portal and to take adequate measures. In future, the sensor shall be able to record further data to allow more profound analyses. Both energy efficiency and engine condition, such as unbalance, misalignments and bearing state, will then be measurable.