Schenck Process introduces ProFlex® C100

17.01.2020

©Schenck

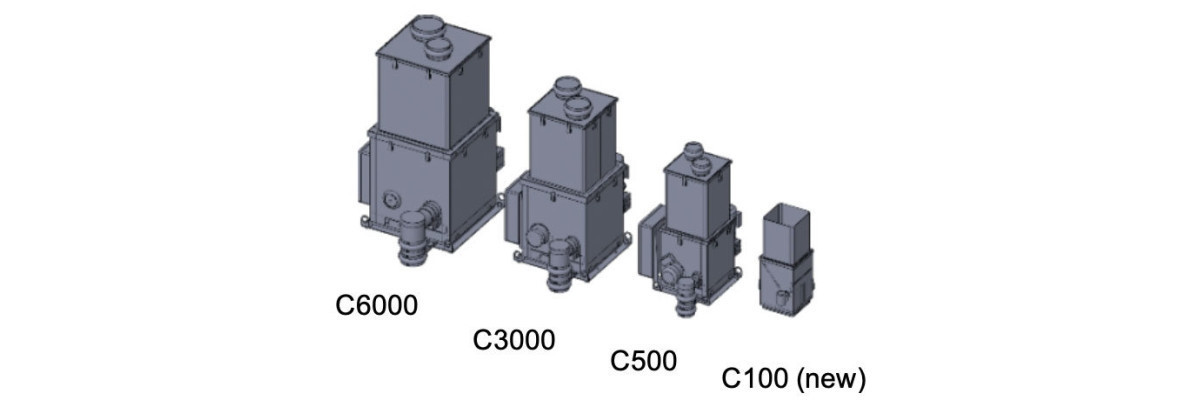

Storage, filling and feeding – three processes for which Schenck Process can provide extensive process knowledge. From a product portfolio perspective, Schenck Process is now completing their offering to best meet market requirements with the newest addition to the ProFlex® C family – the ProFlex® C100.

With ProFlex® C 500, 3000 and 6000, Schenck Process already offers three feeder sizes with a total of five extension hoppers. Now Schenck Process adds to their offering:

·Fit for small extruders: The new ProFlex® C100 is the smallest of the ProFlex® C family and as such also fits on small extrudes. It comes in low weight. Up to five feeders can be grouped around an inlet of a lab or small size extruder.

·Makes the customer flexible: A quick change hopper option in the ProFlex® line for fast and clean change over without disassembling of the feed screw. By keeping several hoppers including screw in stock, a wide range of additives and color pigments can be provided for in a highly flexible manner.

·Ready for sticky powders: The asymmetric design prevents bridging and plugging of sticky material.

·As quick as the customer: The new ProFlex® C100 is equipped with an integrated gearbox for turndown ratios of up to 1 : 120.

·Accuracy ensured: Flexible wall liner massaged at 8 points, which allows a constant and accurate filling of the screw feed element.

·Prepared for the US market: It is NEMA drive ready for compounding and masterbatch, which is crucial for the US market.

The ProFlex® C feeding system is used for the continuous feeding of bulk materials such as powder, granulates, pellets or fibers. Optimized design, flexible hopper walls and flexible installation options make the ProFlex® C a tailored solution for the compound and masterbatch industries.

Schenck Process introduces ProFlex® C100

All of the Schenck Process ProFlex® C loss-in-weight feeder family for the compound and masterbatch industry is characterized by:

·Asymmetric design

·Easy change of discharge / drive side

·8 point massage system

·Easy dismantling and cleaning

·Steep hopper walls

·LIW-critical cabeling encapusalted