Sandvik to showcase innovative rock processing technology at bauma 2025

07.04.2025Sandvik is showcasing its latest lineup of eco-efficient rock processing solutions at bauma 2025, designed to address the increasing demand for safe, efficient, reliable and cost-effective operations.

Featured products include:

- Sandvik 800i cone crusher series: Equipped with the new ACS-c 5 automation system.

- Sandvik vibrating screens and feeders: Featuring the ACS-s condition monitoring system.

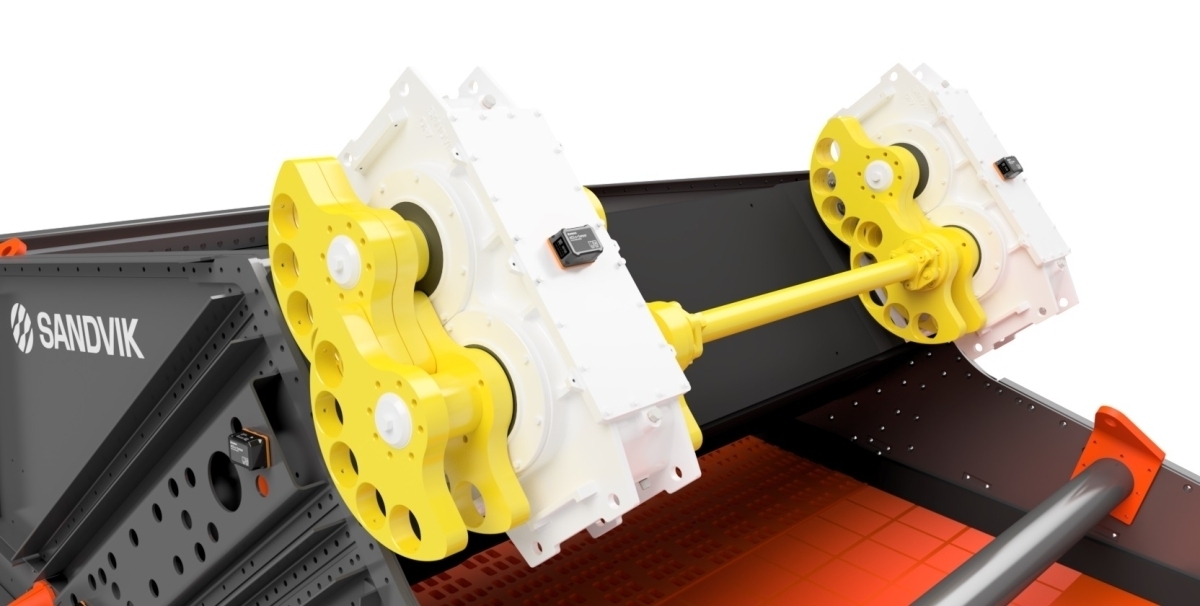

Sandvik ACS-s condition monitoring system

Sandvik ACS-s condition monitoring system

© Sandvik

Digital innovations transform rock processing

Sandvik is at the forefront of delivering solutions that not only meet but exceed evolving industry expectations. According to Richard Harris, President of Sandvik Rock Processing Solutions, digitalization is a cornerstone of innovation, significantly enhancing the efficiency and sustainability of crushing and screening operations.

“Not only is our latest equipment easier to operate, manage, maintain, and service, but it also contributes to our industry’s desire to reduce its environmental impact,” Harris said. “Through our close partnerships with customers and unwavering focus on innovation, we are shaping a future where rock processing is both eco-efficient, productive and profitable."

Sandvik cone crusher CH830i

Sandvik cone crusher CH830i

© Sandvik

Smart and efficient crushing

The Sandvik 800i cone crusher series reflects the company’s commitment to continuous evolution in design, materials and technology. Integrated with the ACS-c 5 automation system, these models combine robust mechanical design with powerful, user-friendly automation, supporting diverse operational needs. ACS-c 5 provides valuable operational insights, enabling smoother operations and improved target achievement.

On display at bauma 2025 will be Sandvik CH830i, one of its most technologically advanced, high-capacity cone crushers. Designed for secondary and tertiary crushing in mining and large quarry applications, it boasts a robust unibody design with few moving parts, ensuring durability and reliability. The top serviceability feature simplifies access, making maintenance both easier and safer. The transition from welded to bolted parts enhances durability, while the new plastic backing-free liners eliminate the need for epoxy resin, significantly reducing waste. Additionally, the direct drive system provides high power with less energy loss, thereby enhancing overall efficiency.

Sandvik's dgital applications are designed to revolutionize screen deck maintenance, uptime and efficiency

Sandvik's dgital applications are designed to revolutionize screen deck maintenance, uptime and efficiency

© Sandvik

Enhanced vibrating screens and feeders

The broad range of Sandvik vibrating screens and feeders are now available with ACS-s - our next generation condition monitoring system, which provides real-time data for informed maintenance decisions, improving operational efficiency and maximizing uptime.

The Sandvik stand will feature a fully operational vibrating screen fitted with ACS-s, allowing visitors to experience the system’s hardware and software in action. In addition, Sandvik will present its groundbreaking digital applications, DeckMapp™ and WearApp™, designed to revolutionize screen deck maintenance, uptime and efficiency.

Integrated solutions for operational efficiency

Both ACS-c 5 and ACS-s are seamlessly integrated with SAM by Sandvik, the cloud-based digital assistant designed to support operational excellence in crushing and screening plants. SAM captures data from all connected Sandvik equipment, offering a comprehensive overview of the entire operation. Operators can monitor equipment status, communicate across teams, receive alerts and notifications and proactively order spare parts from a centralized platform.

Leading the way in sustainable manufacturing

Sandvik's latest innovations are designed to cut energy use, reduce waste and enhance operational efficiency in its customers’ operations. At the company’s eco-efficient foundry in Svedala, Sweden, it produces high-quality parts using over 92 % recycled steel, where in vast majority all powered by renewable energy. By repurposing worn-out wear parts, Sandvik prevented the emission of 16 000 tons of CO2 yearly by avoiding the use of virgin materials. Additionally, Sandvik pioneered the industry's first Environmental Product Declaration (EPD) for manganese crusher wear parts, demonstrating a lower environmental impact and further validating its commitment to sustainability.

Booth C2/149