Metso received order for grinding mills to a copper project in Africa

15.10.2024Metso has been awarded an order to deliver grinding mills to an African copper mining project. The order value is approximately € 20 million and it is booked in the Minerals segment’s third-quarter 2024 orders received.

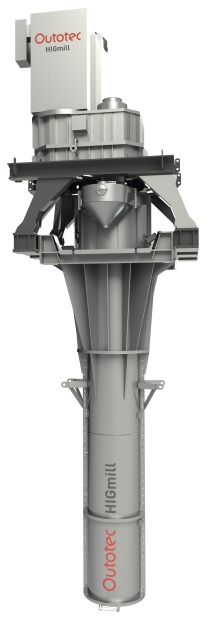

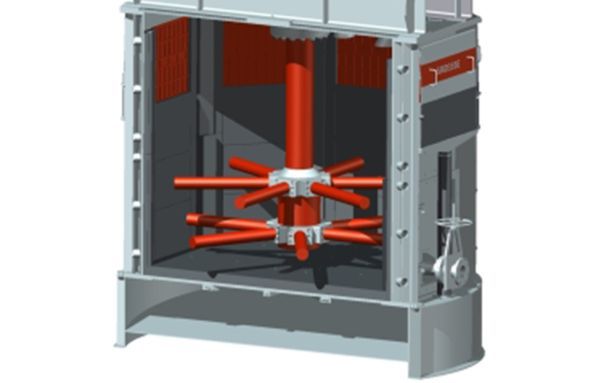

Metso HIGmillTM high-intensity stirred mill

Metso HIGmillTM high-intensity stirred mill

© Metso

Metso’s scope of delivery consists of energy-efficient HIGmillTM high-intensity stirred mills with auxiliary equipment and services.

Metso has experience with over 8000 grinding mill installations globally, including manufacturing and delivering the largest SAG/AG and ball mills in the world. Metso HIGmill™ is an advanced and energy-efficient fine and ultra-fine grinding solution and is part of Metso’s portfolio of stirred mills that meets a wide range of customer requirements. The HIGmillTM takes advantage of gravitational forces and GrindForce™ rotor technology to produce a finer grind for mineral liberation. HIGmillTM is part of Metso’s Planet Positive offering.

Read more about Metso’s stirred mill portfolio here .