Increased grinding capacity with technology from Metso Outotec

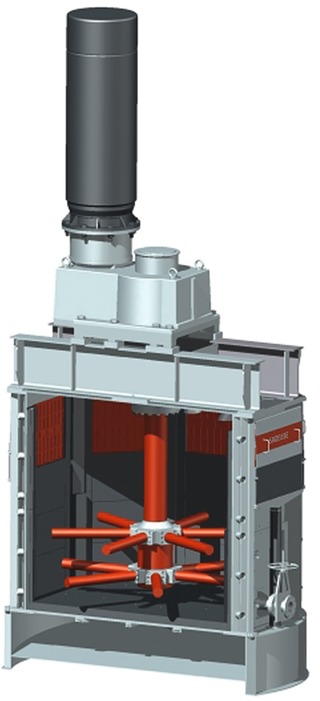

SMD mill

SMD mill

© Metso:Outotec

Boliden Harjavalta has chosen Metso Outotec’s SMD grinding mills to improve the capacity of its slag concentrator. Boliden Harjavalta sustainably produces high-quality metals for European industrial customers. In 2019, the company produced 120 000 tonnes of copper and 26 000 tonnes of nickel. The purpose of the slag concentrator is to recover copper from the slag produced in the copper smelter and to return it to the copper production cycle as high-quality slag concentrate. Grinding is an essential part of the slag concentration process. The order has been booked in Metso Minerals’ Q2 2020 orders received.

Based on tests, Metso SMD mill (Stirred Media Detritor, specialized for fine grinding applications) was chosen as the grinding technology. Maintenance for the SMD is safe and cost-effective thanks to the simple mechanical structure of the mill and the smaller number of moving parts compared to traditional grinding mills.