Komatsu is ready to launch new 13-ton class PC138E-11 electric excavator with lithium-ion battery

02.02.2024Komatsu will introduce the 13-ton class PC138E-11 electric excavator equipped with a lithium-ion battery to the domestic market as a rental machine from January 2024. Komatsu also plans to introduce it to European markets, following Japan. As a market for electrified construction equipment has not yet been established, Komatsu is working to quickly develop this new market with an eye to achieving carbon neutrality by 2050 by expanding its product lineup and meeting customers’ needs.

New 13-ton class PC138E-11 electric excavator with a lithium-ion battery

New 13-ton class PC138E-11 electric excavator with a lithium-ion battery

© Komatsu

By equipping a high-capacity lithium-ion battery and integrating a cooling system for the battery and electric components for this new machine, Komatsu has achieved long operation time while reducing the rear-end swing radius. In regions where electric construction equipment markets are expected to be formed in the future, Komatsu is working to have a variety of customers, with different machine operating conditions and power supply sources, use this machine as a rental machine so that they should be able to experience its environmental friendliness and safety. In this manner, Komatsu will accumulate customer feedback and knowledge and promote the formation of the electrification market.

Komatsu has positioned FY2023 as the first year for the market introduction of electrified construction equipment, and the release of the PC138E-11 is the fourth step in that direction. Hydraulic excavators are the most versatile type of construction equipment, and the 13-ton class is used in a wide range of jobsites and applications, centering on relatively confined spaces, such as urban civil engineering. By capitalizing on the launch of this machine, Komatsu is set to develop a broad range of new customer needs and establish the market for electric construction equipment.

At Intermat 2024, Komatsu will present the PC138E-11 with Smart Construction 3D Machine Guidance. This simple and flexible display system is available as a kit for a wide range of Komatsu machines. A 2D or 3D display can be set up and customised to suit each customer's machine configuration and operating conditions.

DANTOTSU Value is defined as customer value creation that generates a positive cycle of improvement of earnings and ESG resolutions in Komatsu's mid-term management plan, entitled "DANTOTSU Value – Together, to "The Next" for sustainable growth". Through this DANTOTSU Value, Komatsu will strive to create new values in order to take steady steps forward to the next stage for the workplace of the future and pass on a sustainable future to the next generation.

Main features of the products

1. Environmental and Economic Performance:

Achieving zero exhaust emissions with battery-powered and human- and work-environment-friendly features: The battery-powered system produces no exhaust gases, creating a clean working environment. It is friendly to workers and trees around the vehicle, and is widely used at a variety of jobsites, including indoor and urban construction sites.

2. Comfort and Security

Long operation and compact body size achieved with large-capacity lithium-ion battery: The machine is powered by a 225-kWh lithium-ion battery for long hours of operation. The combination of long hours of operation and a compact body size allows for operation in a wider range of construction sites.

Dynamically reducing machine and worksite noise thanks to silent electric motor: Because the power source is a motor, the machine does not generate engine noise. The operator can easily communicate with surrounding workers during the operation, enabling safe and accurate performance.

Comfortable work environment achieved with reduced body no machine vibration and reduction of reduced heat generated from the machine: As the machine is not equipped with an engine, the area around the machine does not get hot and vibration transmitted to the operator has been substantially reduced. The operator feels less stress and fatigue during work, performing comfortable work.

3. Safety, Reliability, and Serviceability

Body structure for safer and easier daily inspections: As routine checkups and high-voltage areas are completely separated, routine checkups can be safely conducted without worrying about high-voltage danger. Furthermore, routine checkups and periodic maintenance items have been substantially reduced because there are no checkup items related to the engine and fuel.

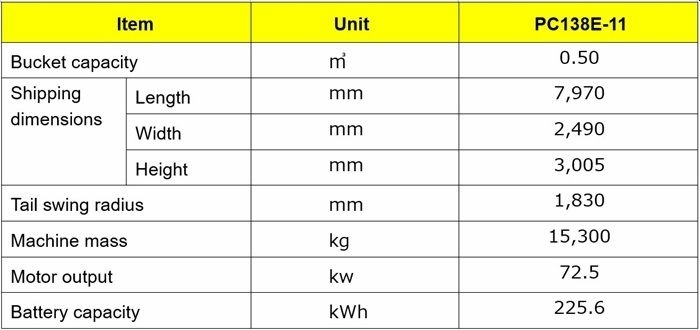

Major Specifications

Hall 5b, E 167