Graphite rounding solutions for lithium-ion batteries

Electromobility is the key to climate-friendly mobility. The growing production of lithium-ion batteries makes the sustainable use of valuable raw materials and resources such as graphite indispensable. Hosokawa Alpine has therefore developed process solutions for graphite rounding so that the raw material can be used optimally.

In the course of the EU climate pact, no new cars with combustion engines are to be registered from 2035 – a clear signal from politics to expand the path for electromobility. Lithium-ion batteries are a basic prerequisite for the construction of transport vehicles with electric drives. The market is experiencing dynamic global growth: While lithium-ion batteries with an energy storage capacity of 200 GWh were produced in 2019, this figure is expected to rise to between 2400 and 6000 GWh by 2030; the global target is up to 10 000 GWh by 2050 [1, 2]. The fields of application range from electromobility to stationary energy storage and batteries for consumer electronics. Until now, cell production has taken place mainly in Asia; Europe is currently striving for independence from Asian suppliers with a new market of its own. Building cell factories on European soil has several advantages: In addition to exemption from customs duties and short transport routes for the raw materials, capacities and quality can be closely adapted to the needs of one’s own market and supply chains can be secured. According to current plans, cell factories for lithium-ion batteries with an annual production capacity of up to 850 GWh are planned in the EU by 2030 [3].

Efficient raw material utilisation through graphite rounding

For manufacturers, this results in the challenge of processing the required natural raw materials as sustainably and efficiently as possible. Synthetic and natural graphite are the most important anode materials for the production of lithium-ion batteries; natural graphite is classified as a critical raw material by the EU Commission [4]. Dynamic growth in graphite demand is in line with the increasing number of lithium-ion batteries: Between 400 000 and 1 600 000 tonnes will be needed globally in 2030, and up to 5 000 000 tonnes in 2050 [5]. To meet the demand for rounded graphite in the long term, the graphite for cell production must be processed with as little loss as possible. In this way, less material is lost and the graphite can be used as effectively as possible. The rounding of graphite brings numerous advantages. On the one hand, it increases the tap density, and thus ensures a better volumetric storage capacity of the battery anode. On the other hand, the graphite rounding improves the intercalation kinetics so that the battery anode can be charged more quickly. In addition, the battery becomes more durable and the cycle stability is increased. Existing processes for graphite rounding only produce a low yield of about 30 to 50 %. Hosokawa Alpine has now developed a new process for graphite rounding that requires fewer machines than before for the same throughput. This not only reduces the space required, but also the effort required for maintenance and servicing. Some graphite producers are still hesitant, but rapid market growth means that now is the right time to invest in machine solutions for graphite rounding. Hosokawa Alpine offers optimised rounding processes that are tailored to the special requirements of natural and synthetic graphite. For natural graphite, the Alpine Particle Rounder APR is the suitable solution; for synthetic graphite, the classifier mill Zirkoplex ZPS. With both machines, the costs for investment and operation are very low, while at the same time a consistently very high product quality is achieved.

Maximum use of the valuable natural raw material

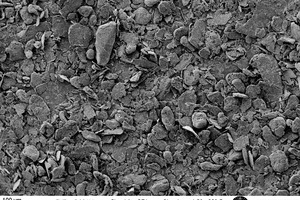

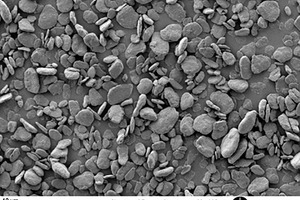

Natural graphite is platelet-shaped and requires more energy to round than synthetic graphite, which is usually already much more spherical after grinding. Hosokawa Alpine has therefore developed a special machine for rounding natural graphite: the Alpine Particle Rounder APR (Fig. 1). The three-stage rounding process begins with pre-crushing on a classifier mill. This is followed by batch rounding with the APR and, as the last process step, sifting for dust removal. The tap density could be almost doubled in this way, and yields of up to 80 % of rounded graphite are achieved (Figs. 2 and 3). The Alpine Particle Rounder APR also impresses with its short process times and high throughputs accompanied by low specific energy consumption. Variable target finenesses from x50 = 10 – 12 µm up to x50 = 22 – 25 µm are possible with the APR.

Advantages of the APR:

Yields of rounded graphite of up to 80 %

Short process times, high throughputs

Low specific energy consumption

Low BET values

Efficient rounding of synthetic graphite

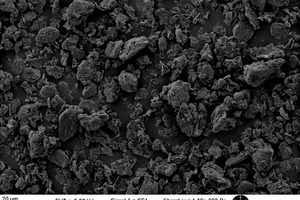

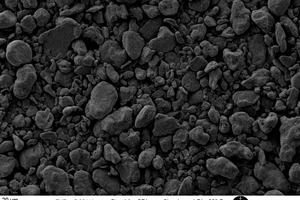

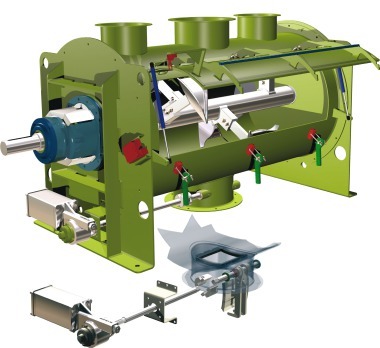

For the rounding of synthetic graphite, Hosokawa Alpine has the Zirkoplex ZPS classifier mill (Fig. 4) in its portfolio. All three required process steps – grinding, rounding and dust removal – are implemented with just one pressure-shock-resistant machine. The graphite is first pre-ground on the classifier mill with the energy-saving designed grinding rotor. Rounding and dust removal are then carried out in batches. The Zirkoplex ZPS also enables an increase in the tap density of the rounded graphite for higher volumetric storage capacity, as well as high throughputs and process yields of up to 90 % with low specific energy consumption (Figs. 5 and 6). It thus completes the solutions for efficient and contemporary graphite rounding from Hosokawa Alpine.

Advantages of the Zirkoplex ZPS:

Yields of up to 90 % of the valuable raw material

High throughputs

Low specific energy consumption

Low BET values

Literature

[1] Dr. S. Michaelis et al., „Roadmap Batterie-Produktionsmittel 2030 Update 2020,“ VDMA Verlag GmbH, Frankfurt am Main, 2020.

[2] Dr. A. Thielmann et al., Energiespeicher-Roadmap (Update 2017) Hochenergie-Batterien 2030+ und Perspektiven zukünftiger Batterietechnologien, Karlsruhe: Fraunhofer-Institut für System- und Innovationsforschung ISI, 2017.

[3] Agrora Verkehrswende, „Batteriestandort auf Klimakurs. Perspektiven einer klimaneutralen Batterieproduktion für Elektromobilität in Deutschland,“ Agora Verkehrswende, Berlin, 2021.

[4] Europäische Kommission, „Widerstandsfähigkeit der EU bei kritischen Rohstoffen: Einen Pfad hin zu größerer Sicherheit und Nachhaltigkeit abstecken,“ Europäische Kommission, Brüssel, 2020.

[5] Öko-Institut, „Strategien für die nachhaltige Rohstoffversorgung der Elektromobilität. Synthesepapier zum Rohstoffbedarf für Batterien und Brennstoffzellen.,“ Öko-Institut, Darmstadt, 2017.

Author:

Benjamin Biber, R & D Manager, Technical Division, Hosokawa Alpine AG, Augsburg/Germany

Benjamin Biber studied environmental and process engineering at Augsburg University of Applied Sciences, graduating with a Master's degree in 2016. Since October 2016, he has been working as a R & D Manager at Hosokawa Alpine AG in Augsburg. His work focuses, among other things, on the rounding of graphite for lithium-ion batteries.