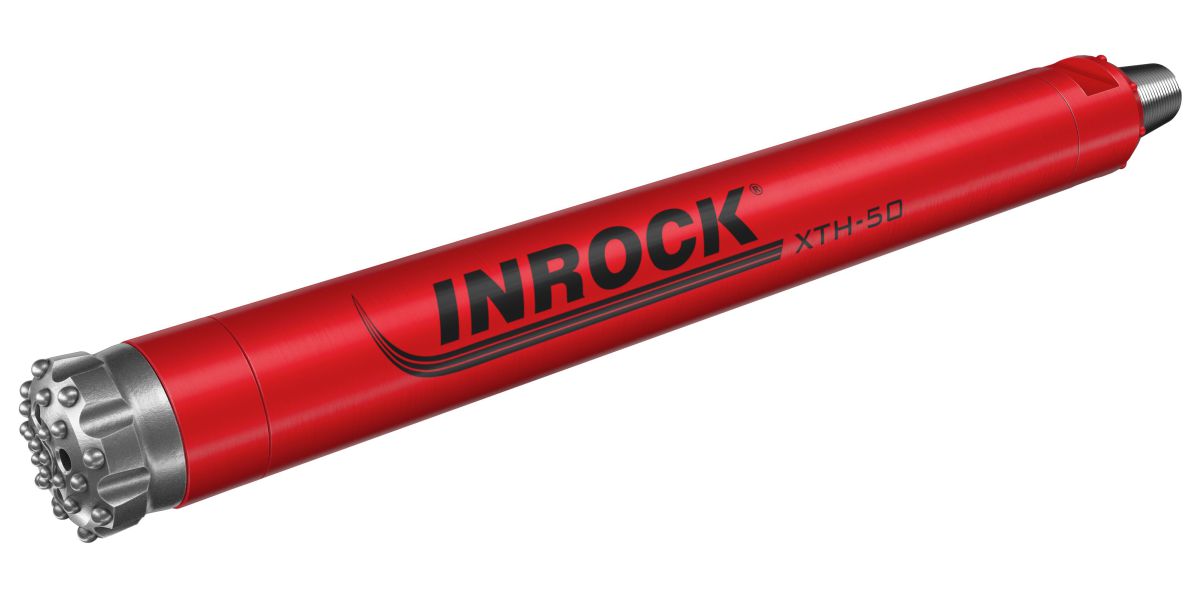

INROCK launches the new XTH Air Hammer

27.05.2021INROCK – one of the global leaders within HDD performance drilling tools – launched the new XTH Air Hammer, designed to drill with a high rate of penetration and lower air consumption, using less fuel without sacrificing speed or power.

© INROCK

The new XTH Air Hammer helps INROCK customers increase their productivity through faster, more effective drilling. It is designed to give drillers everything they need to get the job done thanks to less production time, higher speed, lower repair costs and less production failures. It is simply an air hammer that HDD drillers can count on.

“With the new XTH Air Hammer, we truly show why INROCK is the first choice of partner for any HDD driller. Thanks to its design, that has been developed together with Sandvik, we can help our customers not only make their everyday drilling easier and more reliable, but also help them increase their profitability”, says David Case, President of INROCK.

The all-new design of the XTH Air Hammer features a new spiral piston, which reduces the risk for stress points and potential cracking. And thanks to an all-new guide sleeve, there is no longer the need for a foot valve. With this great design change, compared to competitor hammers, costly downtimes caused by foot valve failures are no longer an issue.

The new XTH Air Hammer is available immediately in sizes of 3.5”, 4” and 5”.