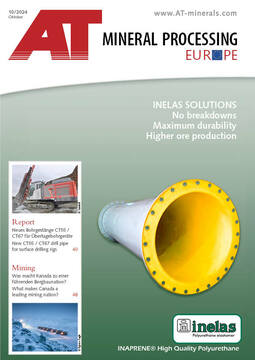

New CT55 / CT67 drill pipe for surface drilling rigs

Sandvik has repeatedly demonstrated through groundbreaking developments that a high-performance overall drilling system is more than just the sum of its components. When all components are perfectly matched to each other, impressive increases in results can be achieved, as Sandvik now proves with its latest product innovation. The first striking feature of the new CT drill system is its innovative curved thread design, but the Sandvik CT is much more. It represents a really effective newly developed system for top-hammer drilling, which brings about a real quantum leap in drilling efficiency through a wide range of optimized details, as a wide variety of application scenarios show after just a few months.

Many large companies have been working with Sandvik for decades. These include, for example, the MHI Group, which operates one of the most important hard rock quarries in Germany in Nieder-Ofleiden, amongst other places. Many people are probably familiar with the location, as the steinexpo takes place here every three years. The company has been relying on Sandvik’s drilling technology for more than 20 years, they currently have a Pantera DP1100i working in the quarry. With a purchase in 2018, it is in its “prime” age and has proven itself over many thousands of meters of drilling in difficult conditions, to the complete satisfaction of MHI. There was a lot of excitement when Sandvik announced in 2023 that it wanted to make a functioning overall package even better, as operations manager Philipp Tuschhoff admits.

“Of course, as a supplier, you have to bring good arguments to convince an important customer like MHI to convert the drilling rig for test operation,” explains Ekkehard Bolle, Sales Manager for the Drilling Tools division. After all, the Sandvik Pantera is not only used for drilling in Nieder-Ofleiden there are also three other locations being drilled with this machine. Initially some conversions were necessary when the new CT55 and CT67 system became available. At MHI, the Sandvik Pantera DP1100i was equipped with a predecessor thread system (ST58). For the conversion, Ekkehard Bolle advised MHI to convert to the larger diameter of the CT67. In order to do this, the Pantera had to be equipped with new clamping jaws, magazine plates and a larger flushing head. The reason for this can be found in the thread design: The energy of the hydraulic drifter is no longer transferred via the bottom of the thread, as is the case with the ST58 tool system, but via the so-called “shoulder” at the male end of the thread. As a result, the shank has become wider and requires a larger flushing head. We trusted Sandvik’s expertise and were not disappointed,” says Philipp Tuschhoff happily afterwards. Test operation has started since mid-July 2023.

In Nieder-Ofleiden, a classic columnar basalt with all its (drilling) problems can be found: a great density and strength, irregularly fissured, especially between the basalt columns, plus with embedded softer tuff zones. Drilling through those soft layers and repenetrating the compact basalt zones, the bending stiffness of the drill string is of immense importance and the drill holes do not deviate. Internal stresses in the drill string are kept at a minimum when, as in Nieder-Ofleiden, the drillholes are drilled up to 30 m into the basalt. This has a great effect when the drill string is extracted and the 4.3-m rods can be uncoupled easily. Comprehensive success was not lacking: As of early November, MHI decided to take over the new CT67 thread system on a permanent basis and has drilled a total of more than 15 000 m with it. “The effects were indeed enormous and immediate,” recalls Philipp Tuschhoff, adding: “The most obvious effect was actually the enormous increase in performance and a fuel saving of 30 % as a direct result.” This could only be explained to a small extent by the larger flushing head, which of course allowed for a higher capacity. Rather, the “inner values” of the tool provide an explanation: Because the design increased the stiffness by 45 % compared to GT60 rods, Sandvik was able to implement an enlarged flushing channel for the CT67 rods.

As a direct result, the total weight of the drill string is almost unchanged compared to the well-known GT65 – another remarkable detail. The increased bending stiffness allows higher percussion and feed pressures to be achieved with high drilling accuracy at the same time. “As an indirect consequence, we were able to select 96 mm Sandvik semi ballistic drill bits that last longer while at the same time improving penetration speed,” says Philipp Tuschhoff, pleased with one of the additional synergy effects. Sandvik product specialist Ekkehard Bolle is also aware of the importance that the curved shaped thread system has in terms of overall performance: “The special geometry associated with the thread design reduces the specific loads by distributing the impact energy over a larger area within the thread, the result is lower tensions in the string.” MHI, in turn, notices its effects in daily use, because both rattling when changing rods and coupling are made much easier. “These are only a few seconds, but in total this makes a considerable acceleration and the automation of the drilling process could also be efficiently improved as a result,” confirms Philipp Tuschhoff.

The fact that the successful optimisations at MHI are no coincidence can be seen at the same time just 50 km further west: Basalt AG (BAG) operates a quarry on Paleozoic diabas at the Stockhausen site. Here, Chief Operations Manager Bernd Eiding has been relying on drilling rigs from Sandvik for many years as well. Since June last year, a Sandvik Pantera DP1500i has been newly commissioned and has been equipped with the CT67 system directly on the recommendation of local Sandvik dealer Ralf Ogroske. It was not necessary to convert subcomponents, especially the flushing head, as the predecessor GT65 tool was already installed here. In diabase, the driller has to reckon with rock sections of varying hardness, and clayey insertions repeatedly make easy drilling difficult. “The differently hard sections and irregular fractures are already a challenge here, and we also drill into the weathered overburdens when expanding the benches,” describes Bernd Eiding. He was really surprised by the obvious increase in efficiency: “Because the CT67 system can be operated at higher pressures, we have since achieved penetration rates of 1.2 to 1.3 m/min – as opposed to 0.9 with the old Tool system.” By reducing the annular space and the associated increase in the flushing speed, precise drilling with increased percussion power is possible. When pulling the string, it is noticeably easier to uncouple the rods, which results in lower tensile stress on all components involved, from the entire drill string to the hydraulic drifter.

One question that was of particular interest to Bernd Eiding and the BAG in this context was the quality of the holes, especially the hole deviation according to the specified planning. “We have some of the holes checked immediately after drilling, if only to make sure that the necessary specifications are met, because nobody wants flyrock here. The result was very convincing. The drilled holes, which are up to 26 m deep, were measured by blasting engineer Joachim Milde (Sprengtechnik 24) with the probe and were extremely accurate, even with a driller who was not very experienced in these operating conditions.” As with MHI, the Sandvik Pantera at BAG is also underutilized with the one location and so the operator supplies other BAG quarries from the Stockhausen site if necessary. “Even after the first experiences here at the site, we believed that the CT67 system could do all rock conditions, whether greywacke, basalt, quartzite or quartz keratophyr,” says Bernd Eiding enthusiastically and: “We were not disappointed.” After no less than 15 000 m of drilling performance with an improved service life compared to the GT65, BAG was convinced to convert another Sandvik Pantera rig to the CT67 drill system.

The experience gained in a wide range of practical operations impressively proves the thesis that even the perfect machine can only ever be as good as the tools with which the actual work has to be done. “The previous Sandvik GT concept has proven itself with our customers over the past 20 years and has ensured extremely reliable and productive drilling,” explains Sandvik man Ekkehard Bolle, adding: “The task was familiar from previous years, but we were able to confidently approach the most demanding customers with the new CT tool, because we had already had the rod system very successfully tested at Kautz drilling company in Dortmund since May 2022 and proven in use.” Furthermore, in 2023, the possible applications of the CT67 from granite to limestone were extensively tested with a Pantera DP1100i demonstration machine all over Germany. These demonstrations ultimately led to the successful sale of the complete Sandvik Pantera and CT67 system to two customers. The successful interplay of good service by the local dealer Ralf Ogroske and Sandvik’s Ekkehard Bolle to adjust the machines exactly according to the requirements of the company and a good price-performance ratio of the tools is demonstrated several times.