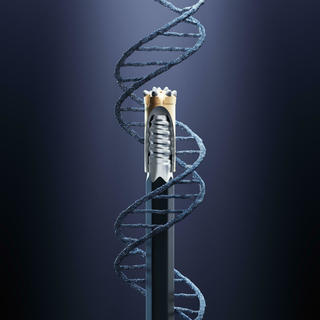

Asymmetric thread concept for mine development

1 Sandvik Alpha™ 340 asymmetric drilling tools

1 Sandvik Alpha™ 340 asymmetric drilling tools

© Sandvik

The new Sandvik Alpha™ 340 thread is designed for use in face drilling and bolting in mine development and tunneling, with hole sizes ranging from 43 to 51 mm. It features an entirely new asymmetric thread profile and has a larger diameter on the bit end thread of the drifter rod, reducing stress levels in critical areas. Uncoupling is also easier than in previous designs, saving both time and effort. Perhaps the biggest potential lies in the increased service life of the drill rod: with Sandvik Alpha™ 340, customers can achieve up to 30 % longer service life – significantly increasing productivity and reducing cost per meter advanced.

2 With Sandvik Alpha™ 340, customers can achieve up to 30 % longer service life

2 With Sandvik Alpha™ 340, customers can achieve up to 30 % longer service life

© Sandvik

“The Sandvik Alpha™ 330 concept has ensured highly reliable and productive drilling over the past 20 years,” said Robert Grandin, Product Manager Top Hammer Underground Rock Tools at Sandvik Mining and Rock Solutions. “With the launch of its successor, we create a revolutionizing new way of working with top hammer rock tools, thanks to its asymmetric design. This new concept will deliver both immediate and long term value for our customers.”

The new thread concept also comes with improved drill bits. Sandvik’s PowerCarbide™ grades will be more widely available in the standard assortment, and many bits get design upgrades with more gauge angles or larger buttons for increased robustness. “The new system is the driller’s choice,” Grandin said. “It is very user-friendly and provides easy uncoupling – which saves a lot of frustration for the driller – but also increases productivity, leading to better drilling results. The new Sandvik Alpha™ 340 thread concept will replace its predecessor Sandvik Alpha™ 330 in a phase-out process over the coming quarters. The new products are now available.