Efficient solutions for environmentally friendly conveying and storage of bulk materials

21.10.2022Around 70 years ago the first AUMUND conveyor with deep-drawn pans for the transportation of clinker was installed. Since then AUMUND Fördertechnik (Rheinberg/Germany) has become an international market leader in products and efficient solutions for the conveying of especially hot and abrasive bulk materials in the cement industry and related sectors worldwide. The range of these products and solutions encompasses feeding, extraction and transportation solutions in all stages of cement production processes, in particular from the cement mill to clinker dispatch.

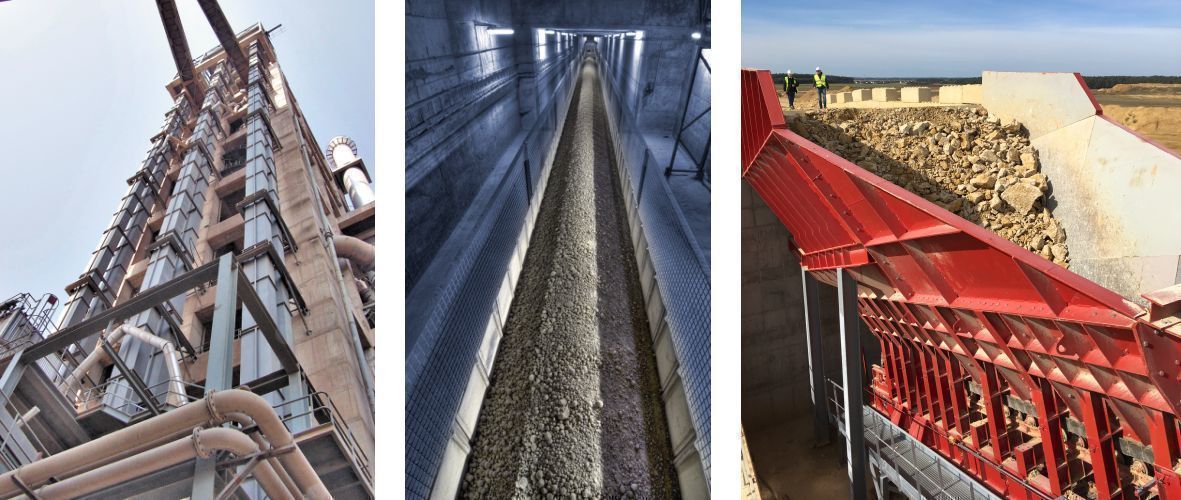

Examples of AUMUND Equipment: Bucket Elevator (left), Pan Conveyor (middle), Apron Feeder (right)

Examples of AUMUND Equipment: Bucket Elevator (left), Pan Conveyor (middle), Apron Feeder (right)

© AUMUND

Building on extensive product and process knowledge in the cement industry, AUMUND has also been very successful with its equipment in minerals/raw materials and mining. Solid know-how has been developed over time in the many diverse methods of mining, processing and refining different natural resources with the most varied of characteristics. AUMUND machines are also utilised for the conveying and storage of fertilisers and non-metallic minerals, as well as in iron, steel and aluminium production and in foundries. AUMUND creates flexible, individual solutions for their customers, based on standard components. Bucket elevators, pan conveyors, chain conveyors, silo technology and extraction and discharge systems are designed with maximum capacities and meet the highest technical demands. The installation on site is supervised by specialised engineers and after sales service personnel.

Drag Chain Conveyor type LOUISE

Drag Chain Conveyor type LOUISE

© AUMUND

Vertical conveyors of up to 175 m and higher, solutions for crusher feeding and discharge of up to 11 000 t/h as well as pressure shock resistant conveyors are representative examples of the strength of the AUMUND solutions. Metered silo feeding and metered silo extraction as well as dust suppressed loading of ships, railway wagons and trucks complete the product portfolio of the AUMUND Group of companies.

The minerals sector is increasingly convinced by AUMUND’s worldwide experience in the construction of specialised machinery. Besides the flagship classics, such as belt bucket elevators and pan conveyors, the installed heavy plate conveyors for crusher feeding are proving that AUMUND has more to show for itself than decades of experience in limestone processing.

Samson® Material Feeder (fixed)

Samson® Material Feeder (fixed)

© AUMUND

Growth in market share has been achieved over many years, not only in the sale of new machinery, but also by AUMUND’s after sales service and conversion departments, with their own solutions for increasing productivity and minimising manufacturing down times and maintenance costs.

PREMAS® maintenance solutions

PREMAS® has been the flagship of the customer service strategy of the AUMUND Group since 2004. The purpose and objective of PREMAS® is to offer a comprehensive maintenance programme for all kinds of bulk materials handling equipment in the cement industry, in power plants in the iron and steel industry and in many other key areas.

PREMAS® 4.0 at Jura-Cement-Fabriken AG in Switzerland

PREMAS® 4.0 at Jura-Cement-Fabriken AG in Switzerland

© AUMUND

The service concept of the AUMUND Group today is built on two pillars, the classic in-person analogue on-site inspection of PREMAS® Preventive Maintenance Service, carried out by certified personnel, and the new predictive digital monitoring system PREMAS® 4.0 Predictive Maintenance Solution. The PREMAS® 4.0 online monitoring solution which was launched at the beginning of 2021 has already proved its viability in practice in many installations all over the world. At the same time PREMAS® 4.0 is part of the PREMAS® 360° Maintenance Packages which have been on the market since the end of July 2021.

AUMUND is always in close proximity to its customers, thanks to its fifteen locations in Europe, Asia, North and South America, along with five service centres and spare parts warehouses in Germany, USA, Hong Kong, Brazil and Saudi Arabia.

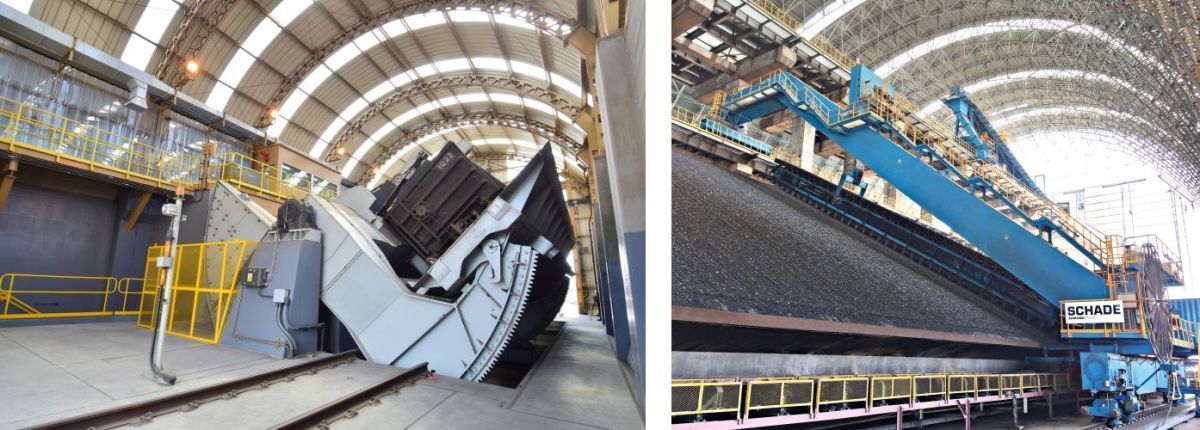

Examples of SCHADE Equipment: Circular Storage (left), Portal Scraper Reclaimer –Longitudinal Storage (right)

Examples of SCHADE Equipment: Circular Storage (left), Portal Scraper Reclaimer –Longitudinal Storage (right)

© AUMUND

SCHADE Lagertechnik

SCHADE Lagertechnik (Gelsenkirchen/Germany) has been one of the leading manufacturers of stacking and reclaiming technology for bulk materials stockyards and blending beds for over 140 years. Its roots are in the coal-fired power industry, but it has also become a market leader in the cement industry with its longitudinal and circular storage and blending bed technology.

Examples of SCHADE Equipment: Wagon Unloading System (left), Semi-Portal Scraper Reclaimer (right)

Examples of SCHADE Equipment: Wagon Unloading System (left), Semi-Portal Scraper Reclaimer (right)

© AUMUND

SCHADE also offers machinery and solutions for customers in the minerals/raw materials industry as well as in ports and terminals, taking advantage of the international network of the AUMUND Group’s worldwide sales partners.

SAMSON Materials Handling

The NEW evolution of materials handling equipment from SAMSON Materials Handling Ltd is designed to answer all materials handling requirements of busy plants in all industries, ports, terminals and stockyards, offering zero dust emissions covering a wide range of applications, thus resulting in reduced operating costs and increased efficiencies.

Examples of SAMSON Equipment: STORMAJOR®: New generation (left), SHIPLOADER: New evolution (right)

Examples of SAMSON Equipment: STORMAJOR®: New generation (left), SHIPLOADER: New evolution (right)

© AUMUND

SAMSON will present the newly designed STORMAJOR® and the evolution of the SAMSON SHIPLOADER and ECO HOPPER at Bauma 2022. Information about the full range of products, including the world-renowned mobile Samson® MATERIAL FEEDER is available at the AUMUND Group of companies stand.

The NEW Generation SAMSON STORMAJOR® is a versatile multi-purpose machine designed for precision stockpiling and loading combining a mobile truck unloader with a movable boom.

The newly evolved SAMSON SHIPLOADER is based on a tubular boom design, providing a lighter more sturdy structure. Modularisation and standardisation have led to the creation of multiple types of shiploaders with a range of different boom lengths and a choice of chassis types.

Examples of SAMSON Equipment: ECO HOPPER: Improved efficiency (left), Samson® MATERIAL FEEDER – mobile (right)

Examples of SAMSON Equipment: ECO HOPPER: Improved efficiency (left), Samson® MATERIAL FEEDER – mobile (right)

The SAMSON ECO HOPPER provides an efficient, flexible solution to importing dry bulk materials with a variety of dust suppression or dust extraction measures to reduce the spread of fugitive dust.

The mobile Samson® MATERIAL FEEDER is the ultimate truck unloader and can be a fixed installation, wheel or track mounted and compatible with a wide range of auxiliary downstream equipment.

AUMUND Fördertechnik: Hall B2, stand 143

SCHADE Lagertechnik / SAMSON Materials Handling: Hall C2, stand 139