How an inventor and engineer’s office became an international conveying

and storage technology brand

Today AUMUND Group machines, systems and process technologies are in operation in metallurgy, mining and minerals, lime and gypsum, chemicals - in particular fertiliser, foundries, power plants, agribulk, ports and terminals, as well as in the area of alternative fuels with its current significance in environmental politics and environmental technology. The 100-year history and development of AUMUND spans three generations and is inextricably linked with the business leaders Prof. Dr.-Ing. h.c. Heinrich Aumund, Günter-Claus Aumund and Franz-W. Aumund, who is currently Chairman of the Advisory Board.

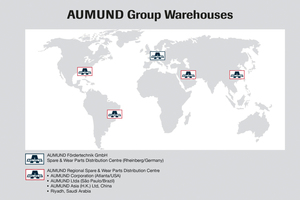

The AUMUND Group today comprises the following companies: AUMUND Fördertechnik GmbH/Rheinberg, Germany, SCHADE Lagertechnik GmbH, Gelsenkirchen/Germany, SAMSON Materials Handling Ltd, Ely/UK, TILEMANN GmbH Chains & Components, Essen/Germany, AUMUND Group Field Service GmbH and AUMUND Logistic GmbH, both located in Rheinberg/Germany. The global conveying and storage business is currently driven internationally by 20 locations in Europe, North and South America and Asia, supported by five ServiceCentres in Germany, Hong Kong, USA, Brazil and Saudi Arabia, and reinforced by approximately 80 representations and a network of around 100 supervisors and inspectors who advise on and accompany installation, commissioning and on-site inspections with the PREMAS® Preventive Maintenance Service for AUMUND, SCHADE and SAMSON machines as well as for those of other manufacturers.

Effective mid-2022, after 100 years of family management Franz-W. Aumund, who had been Managing Proprietor of the AUMUND Group for 38 years, has handed over his operational activities to the Management of AUMUND Fördertechnik, in the persons of Dr Pietro de Michieli, Reiner Furthmann and Uwe Altena. Dr Pietro de Michieli has been Managing Director Sales for four years and has now been appointed additionally as CEO of AUMUND Fördertechnik GmbH and AUMUND Holding B.V. Reiner Furthmann has been responsible for technology, design and production at AUMUND Fördertechnik GmbH for around 20 years, and was appointed Managing Director Technology in March 2018. Uwe Altena has held the function of Commercial Managing Director since mid-2021.

Mergers and acquisitions purposefully implemented

Acquisitions are an important source of richness of ideas and strength of innovation for the AUMUND Group. With the acquisitions of Maschinenfabrik LOUISE GmbH in 1991 and WTW Engineering Maschinen- und Förderanlagen GmbH in 2006, AUMUND expanded its product range and its product know-how in Rotary Discharge Machined and Drag Chain Conveyors. The purchase of the spare parts business for Silo Discharge Systems of Besta & Meyer GmbH in 2014 fitted with this portfolio, and the acquisition of the spare parts business of KoWey GmbH in 2021 was appropriate in connection with Bucket Elevators.

Diversification was the strategy behind the acquisition of Gustav Schade Maschinenfabrik GmbH in Dortmund, today SCHADE Lagertechnik GmbH, and of British company B&W Mechanical Handling Ltd, today SAMSON Materials Handling Ltd, in 2001 and 2002 respectively. Both companies serve market segments adjacent to those of AUMUND. B&W/SAMSON manufactures mobile Material Feeders, Shiploaders and Ecological (Eco) Hoppers, which are predominantly used in ports and terminals but also in industrial applications. SCHADE designs and supplies machines such as Stackers and Reclaimers for bulk materials stockyards and blending beds, which are particularly in demand for handling bulk materials in the most varied of key industries. The Rail Wagon Tipplers which were originally sold by AUMUND were integrated in to the SCHADE portfolio at the beginning of the 2010s. This was not only because SCHADE had a customer base in coal handling operations, but also because Wagon Tippler specialists are employed by SCHADE in the design office in Bristol/UK.

With the acquisition of Th. Tilemann GmbH Gelenkketten- und Räderfabrik, Essen/Germany, in 2016, the AUMUND Group gained an experienced manufacturer of high-quality chains and associated components. In the integration process the company was re-named TILEMANN GmbH, and equipped with the latest production and assembly technology for the fabrication of AUMUND Bucket Elevator Chains, and also conveying chains to supply to manufacturers of stockyard and blending bed equipment and scraper conveyors, including SCHADE.

Digitalisation is on the advance at AUMUND

The topic of digitalisation is gaining in significance for the future in the AUMUND Group. One example of this is the PREMAS® 4.0 Predictive Maintenance Solution. The system for predictive maintenance was developed together with PREMAS AG, Switzerland, and it monitors safe, energy-efficient machinery operation and analyses the condition of the machine with the aid of algorithms. The AUMUND Group is currently offering PREMAS® 4.0 predominantly for Belt Bucket Elevators, various types of Chain Bucket Elevators, Pan Conveyors, and for the CENTREX® Silo Discharge System. PREMAS® 4.0 can also be installed on equipment made by other manufacturers, for example as part of a conversion.

Key industries for bulk materials – the “home” of AUMUND Group products

Way over half of the 24 000+ pieces of equipment operate in the cement industry all over world. The logistics of the various raw materials, combustibles and additives play a significant role in the cement production process. Limestone and other raw materials must be kept available in sufficient quantities to keep the production process running continuously, with an additional buffer in case there is an interruption in supply. The careful planning and design of clinker storage and clinker conveying makes a major contribution to the economic viability of the complete plant. This is a discipline in which AUMUND Fördertechnik has more than 60 years of technological expertise.

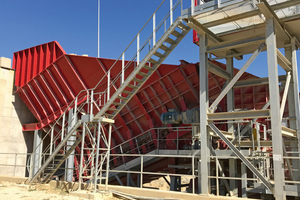

AUMUND products also have a long tradition in the mining and minerals sector, with optimised solutions for every process stage for conveying, storage and loading of often abrasive and sticky bulk materials. AUMUND has experience with the handling of the most varied of materials such as basalt, bauxite, dolomite, ores, fly ash, urea, potash, limestone, clay, petcoke, phosphate, pozzolan, salt, sand, sulphur, and zinc oxide. The application and the characteristics of the materials determine the conveyor. Precise planning is of the utmost importance because this is the basis for the economic success of the plant.

AUMUND equipment is also part of the machinery in power plants for example for reception of coal, calorific domestic waste (RDF), biomass or limestone in various types of firing plant whether it be grate firing, pulverised coal firing or fluidized bed combustion, as well as for export of materials such as gypsum, ash, sludge and dust.

Wherever mobility and speediness are required

For import and export of material the AUMUND Group offers a very wide spectrum of machines and equipment in conveying and storage technology. For ports and terminals the mobile (i.e. driven) ship loading and unloading systems such as Shiploaders, Eco Hoppers, and the Samson® Material Feeder are particularly attractive.

SAMSON Materials Handling has developed a range of ship loading and unloading equipment, adapted to the handling of dry bulk materials, which offers flexibility both for operators of existing berths and for high-performance loading. Mobile Shiploaders, Material Feeders and also the STORMAJOR® can be operated on any quay independently of each other or parked out of the way until they are required for the next job. The mobile technology is configured by SAMSON to create a system which matches precisely the requirements of the individual port or terminal.

Service is the key to customer proximity and customer satisfaction

The AUMUND Group offers extensive After Sales and Customer Support Services all over the world, ranging from consulting to upkeep, preventive and predictive maintenance (PREMAS® and PREMAS® 4.0), repairs and spare parts, to the training of customers’ maintenance personnel. AUMUND Group Field Service GmbH, which was incorporated in 2017, ensures a globally standardised commitment to quality in installation and commissioning of AUMUND, SCHADE and SAMSON machines, and also of equipment manufactured outside the Group, with its international network of around 100 supervisors and inspectors.

Provision of high-performance service was also the basis for the incorporation in 2007 of AUMUND Logistic GmbH as an autonomous company. The focus of its activities is worldwide dispatch of machines and machinery parts by sea freight, air freight and land transportation for AUMUND, SCHADE, SAMSON and TILEMANN as well as for the overseas AUMUND companies. Not only spare parts packages and products manufactured by AUMUND are forwarded, but collections are also organised of machines and parts from other locations which need to be transported to a customer or installation site elsewhere.

“WE CONVEY A GREENER FUTURE”

“The linking of ecological aspects and business considerations, for the benefit both of our customers and of the AUMUND Group itself, has defined our thinking and actions for decades, in fact even before concepts such as conservation, sustainability and reduction of CO₂ emissions became important for so many companies all over the world. In this the AUMUND Group is one of the pioneers in the bulk materials conveying and storing sector,” says Franz-W. Aumund.

For reduction of dust emissions, and for other reasons of environmental safety, SCHADE offers covered storage systems for bulk materials volumes of 800 000 t or 1 000 000 m3 even on a small surface area. Stockpiling is carried out by mobile Tripper Cars installed beneath the roof of the storage building, and the pile is reclaimed by Full-Portal or Semi-Portal Reclaimers. Depending on customer requirements or official regulations, the equipment can be adapted to the height of the storage building using a design incorporating two booms on the Reclaimer. In an indoor circular storage facility, storage capacities of 360 000 t are achievable.

The SAMSON Eco Hopper fulfils strict standards for the reduction of dust emissions. The Eco Hopper is used for importing bulk materials in ports and terminals, and has a comprehensive range of dust protection features, including a system which reduces the impact of sidewinds, the Flex-Flap dust sealing system and a mechanically driven sliding roof.