Construction machinery and building materials plant sectors ride roller coaster

23.11.2021It could be even better. The order intake is booming. But delays in the supply chain as well as a lack of raw materials and rising material prices are leading to delivery problems and uncertainties in the calculation. The industry is not yet able to compensate for the losses from 2020. Additional tasks due to the climate targets require political support.

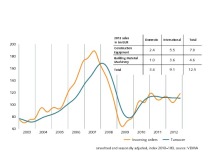

From January to August of the current year, industry sales of German-manufactured construction machinery are 14 % higher than in the same period of the previous year, adjusted for prices. If this trend continues until the end of the year, the industry will almost reach the level of 2019. The industry has recovered from the shock of the pandemic year. Construction equipment manufacturers are worried about suppliers who cannot deliver certain components such as semiconductors.

Joachim Strobel, deputy board member at VDMA Construction says: "It's not up to us. We could deliver if the conditions allowed it. The demand for semiconductors is huge. Large companies in the electronics and automotive industries will be served first, if at all. Mechanical engineering, as an industry dominated by medium-sized companies, is lagging behind. The ongoing shortage of skilled workers exacerbates the situation."

There must be no collateral damage in the construction industry

It is not only economic issues that are driving manufacturers. Political and legal requirements due to climate targets present them with additional challenges. The industry is calling on politicians to differentiate and be ready for concepts that are open to technology. "It cannot be that in the course of new exhaust gas directives we are accepted as collateral damage of a general ban on internal combustion engines. The diesel engine for construction machinery, powered by e-fuels, which are synthetic fuels, is an environmentally friendly model that can prove its worth. Other alternative drive concepts require an infrastructure that is hardly feasible in most of our application areas," emphasizes Franz-Josef Paus, chairman of the trade association.

Policymakers must act more quickly

Even though the building materials plant sector is more heterogeneously positioned and plans in longer cycles, it is struggling with similar supply chain difficulties in the current year. At the same time, the order books here are also very well filled again. Cost pressure is particularly high in the plant engineering sector. Long project durations with uncontrollable raw material prices make stable costing difficult. The release of CO2 in the manufacturing process of building materials is another problem that needs to be eliminated. New processes already exist, but the political framework conditions for them often do not.

The principle of technological openness must apply here just as it does in all areas. The key to innovation is open competition. "We are always ready to exchange views with those with political responsibility on technical contexts and prerequisites. How can we best meet sustainability criteria? This question will accompany us in the future. In doing so, we should always keep the big picture in mind," explains Georg Baber, Chairman of the VDMA Cement, Lime and Gypsum Plants Division. One example is carbon dioxide capture in the cement industry. "Climate neutrality requires the widespread use of new process technologies, such as carbon capture use or storage. The new German government must quickly create the necessary infrastructures to help these future technologies achieve a breakthrough," appeals Christoph Reißfelder, Group Communication & Investor Relations at HeidelbergCement AG as a guest at the VDMA.