14.06.2013 / Metso receives two repeat orders

Metso has signed two repeat orders with Altay Polimetally LLP for their open pit copper mine in Almaty/Kazakhstan. The orders include the design, supply, installation and commissioning of complete secondary, tertiary and quaternary crushing and screening plants as well as an automation system. The combined value of the orders is 25 million €. The two new contracts follow the delivery of the world's biggest fully mobile crushing and conveying system, signed in June 2012 for a value of 11 million €. To achieve the customer's objective for a minimum number of operators, Metso also supplies Altay a complete automation system to run the whole process. The electrical systems can withstand the harsh climatic conditions (from +30°C to -30°C) and provide efficient plant control. The secondary and tertiary crushing plant order was included in Metso Mining and Construction's fourth quarter 2012 orders received, and the quaternary crushing plant in the first quarter 2013 orders received. The installations will be delivered by July 2014.

Crushers to allow high output

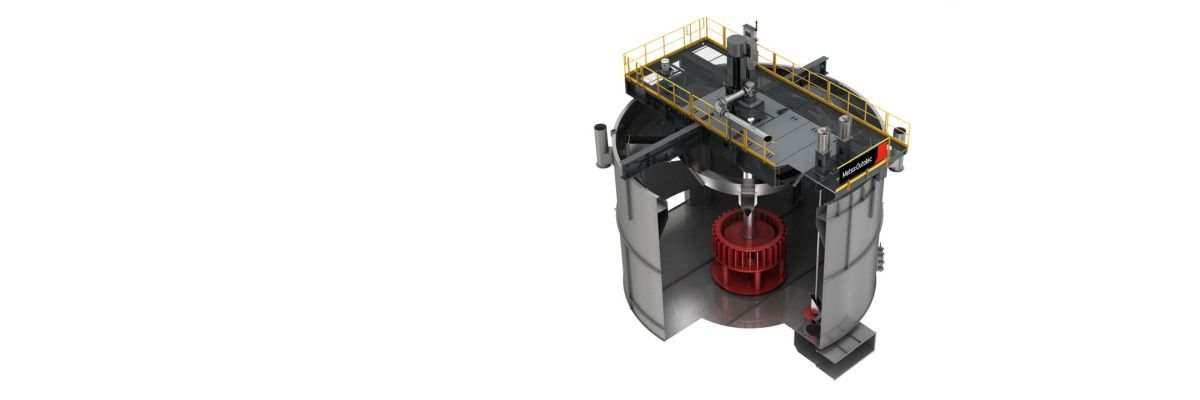

The secondary and tertiary plants include one GP500S cone crusher with large feed opening, and two HP5 cone crushers with high reduction ratio. Two high-efficiency MF 3085-2 screens will be used for screening. The planned output of the copper ore processing plant is 550 metric t/h, resulting in 3 million t/a of 0/10 mm sized end products. The quaternary crushing plant will produce 0/3 mm sized ore with a capacity of 450 metric t/h. Two Barmac 9100 vertical shaft impactors are used, one of them in operation and one stand-by. Here, another two MF 3085-2 screens are used.

Altay Polimetally LLP, based in Almaty/Kazakhstan, will extract at the new mine copper ore including gold. The planned ore extraction will be 3 million t/a, and including host rock 10 million tons. The CEO and Chairman of the Board of Altay Polimetally LLP Mr Yun previously held the position of CEO of Kazakhmys Corporation between 1995 and 2006. He was instrumental in increasing the production of copper cathodes from 90 000 to 420 000 t/a.