Saving environment and costs

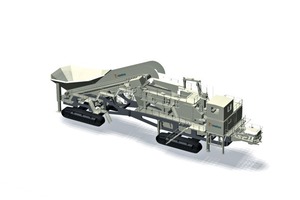

Metso will supply world’s biggest fully mobile, track-mounted crushing plant to Altay Polimetally LLP copper mine in Kazakhstan (Fig.). The giant mobile jaw plant saves environment and costs by decreasing dump truck traffic at the open pit copper mine. The contract also includes large mobile feeding and conveying systems to move the crushed copper ore for further processing, and installation supervision and training. The complete value of the order exceeds 11 million €. The plant will be used at primary crushing stage at Altay Polimetally’s new open pit mine, situated in the Karagandy region. Metso’s mobile crushing equipment to Kazakhstan will be delivered within the last quarter of 2013.

The almost 400 t weighing Lokotrack LT200 – biggest ever built – is the key part of the system. The unit processes copper ore with a nominal capacity of 2500 t/h. The complete mobile system weighs over 800 t, though can be moved easily along the mine face. To withstand the harsh climate conditions during the winter, the whole mobile system is electric driven. The operational temperatures at the mine site vary from +35 °C to -35 °C. At the new open pit mine, the blasted copper ore is fed using Metso’s MAF210 mobile apron feeder to Lokotrack LT200 jaw plant, and then conveyed using Nordberg LL16 mobile conveying system, and track-mounted stacker to the mine’s conveyor network. The loading height of the tracked mobile apron feeder is 6 m, and it has a feed hopper volume of 24 m3. The LT200 jaw plant, equipped with Metso’s biggest C200 jaw crusher, can crush ore feed lumps up to 1.2 m in size. The wheel-mounted LL16 mobile conveyor has two conveyor elements, each 42 m long. The track-mounted stacker has a discharge height between 3-10 m.

Altay Polimetally LLP, based in Almaty/Kazakhstan, will extract at the new mine copper ore including gold. The planned ore extraction will be 3 million t/a, and including host rock 10 million t.