Agnico Eagle’s Goldex mine achieves significant carbon emissions reduction with railveyor system

05.09.2024Agnico Eagle Mines Limited (AEM) revealed its findings on the efficiency and environmental impact of the Railveyor system implemented at its Goldex Mining Complex. The whitepaper, published by Railveyor and Agnico Eagle, details the system's profound influence on reducing operational costs, enhancing safety, and cutting greenhouse gas emissions.

An aeriel view of the Agnico Eagle mining complex located in Val-d’Or, Quebec

An aeriel view of the Agnico Eagle mining complex located in Val-d’Or, Quebec

© Agnico Eagle Mines Limited

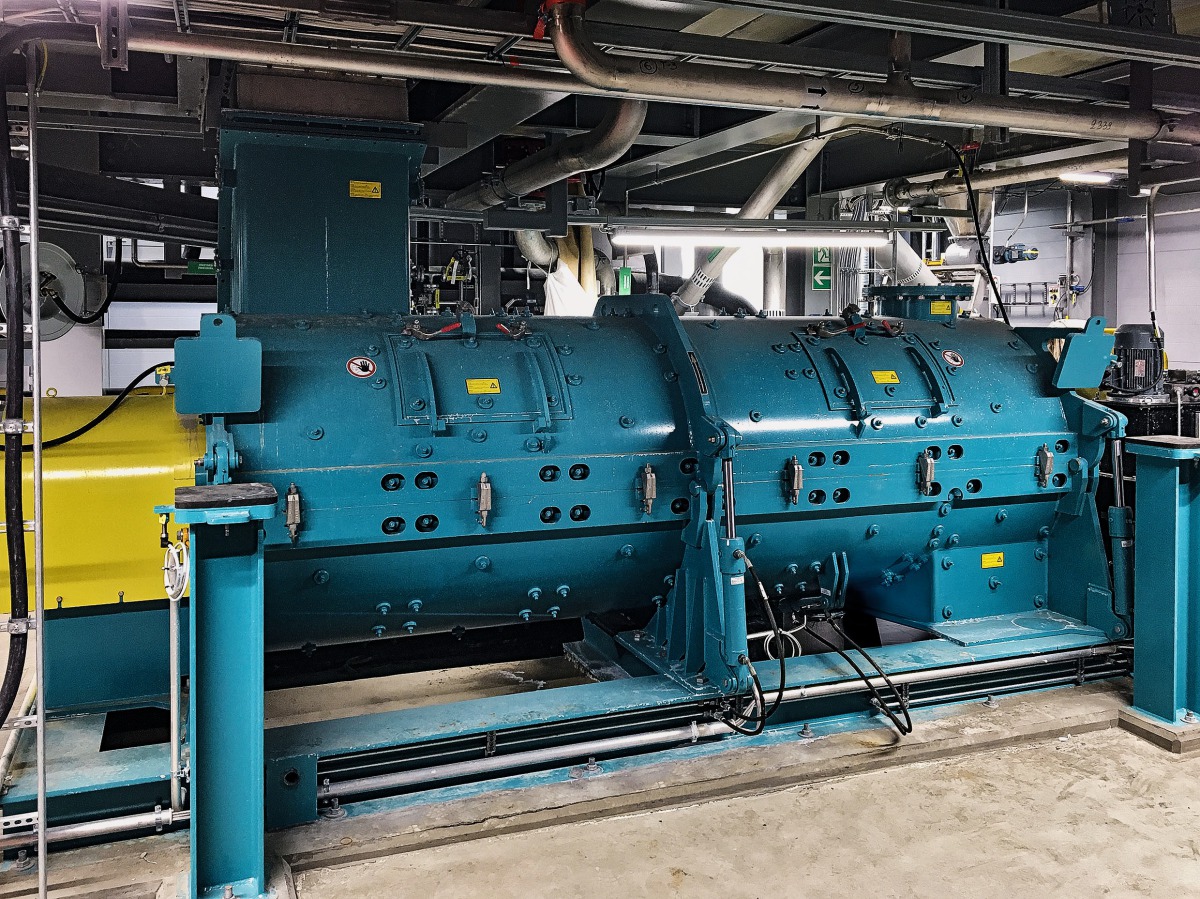

Located in Val-d’Or, Quebec, the Goldex mine, an underground gold operation, faced logistical challenges due to its deeper zones and low-grade ore. To address these, AEM integrated the Railveyor system into its operations in 2017, replacing traditional diesel truck haulage with this advanced all-electric solution. The results have been transformative.

According to AEM’s internal studies, the Railveyor system has achieved up to a 39% reduction in mine-wide emissions compared to diesel trucks, a significant step towards the company’s commitment to achieving Net Zero by 2050. The system's energy efficiency was also validated by a study from NRCan-CanmetMINING, confirming that the Railveyor operates within 6% of its expected energy usage. With its low operational costs—reducing OPEX by as much as 75% compared to truck haulage—Railveyor has proven itself as a cost-effective, sustainable alternative for material transport in mining.

Railveyor's automated system allows for loaded trains traveling to discharge and empty trains returning to load to pass one another simultaneously preventing delays in the production haulage cycle

Railveyor's automated system allows for loaded trains traveling to discharge and empty trains returning to load to pass one another simultaneously preventing delays in the production haulage cycle

© Railveyor Technologies Global Inc.

Christian Lessard, Maintenance Superintendent at Goldex, emphasized the system's success: "Goldex Railveyor has been optimized since 2017, resulting in strong production in recent years. The system integrates the latest technologies like LTE networks and AI, operating in line with theoretical energy consumption models. The stability and predictability of electrical energy costs, as opposed to fossil fuels, further contribute to the overall benefits.”

Tas Mohamed, interim CEO of Railveyor

Tas Mohamed, interim CEO of Railveyor

© Railveyor Technologies Global Inc.

Tas Mohamed, interim CEO of Railveyor, commented on the achievement: "The success of the Railveyor at Goldex highlights the importance of collaboration between our team and AEM. This partnership has demonstrated that Railveyor is not just a viable alternative to traditional methods but a superior one in terms of safety, cost, and environmental impact."

Adding to this, Charles Gillies, Chairman of Railveyor and Managing Director at Resource Capital Funds (RCF), a global critical minerals and mining alternatives investment firm, said: "We are proud to have supported Railveyor within RCF Innovation II in bringing this innovative technology to market. The positive impact at Goldex underscores the value of investing in sustainable and transformative mining solutions that can help enable the energy transition and meet the mining industry's challenges today and in the future."

As the mining industry continues to push towards sustainability, the success of the Railveyor system at Goldex serves as a benchmark for other operations. With its ability to reduce emissions, increase safety, and lower costs, Railveyor is setting new standards in mining.