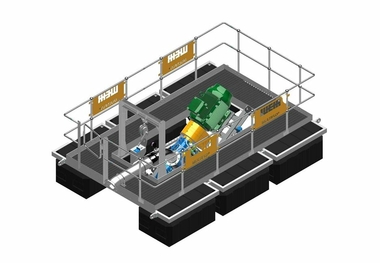

Weir introduces ENDURON® Orbital vibrating screens with all-bolted construction

New ENDURON® Orbital vibrating screen

New ENDURON® Orbital vibrating screen

© Weir

The ENDURON® Orbital range is available in two screen types: the E series: Elliptical Motion Horizontal Screens and the C series: Circular Motion Inclined Screens. Both screen types incorporate the latest technologies to deliver exceptional performance in a broad range of sand and aggregate and mining duties.

A wide operating window provides flexibility to adjust screen settings in line with changing applications or feed conditions, without compromising the equipment’s structural integrity and minimising the risk of structural failure related to harmonic resonance. The modular screen construction ensures that individual components can be easily replaced. Common interchangeable screen parts reduce inventory overflow and simplify maintenance. Both screens are digitally enabled, including our modular exciter technology, which senses and reports on the condition of the exciter. The exciter itself features a bolt-on/bolt-off design, meaning they can be easily changed on site and refurbished in a mechanical workshop.

All ENDURON® products are fully supported by the Weir service network, offering service, support, and local expertise across the globe. Corné Kleyn, Global Product Manager for Vibrating Screens said: “We at Weir are excited to bring this revolutionary new screening technology to the market. The team has worked hard for the past two years to bring our customers a product that is reliable with the lowest total cost of ownership. Our first screen has been successfully installed and commissioned at a large global customer and we are gaining momentum with more units planned for both the European and North-America markets.”