Substantial cost savings with effective dust control

1 Effective dust control with the AirScrape

1 Effective dust control with the AirScrape

© ScrapeTec

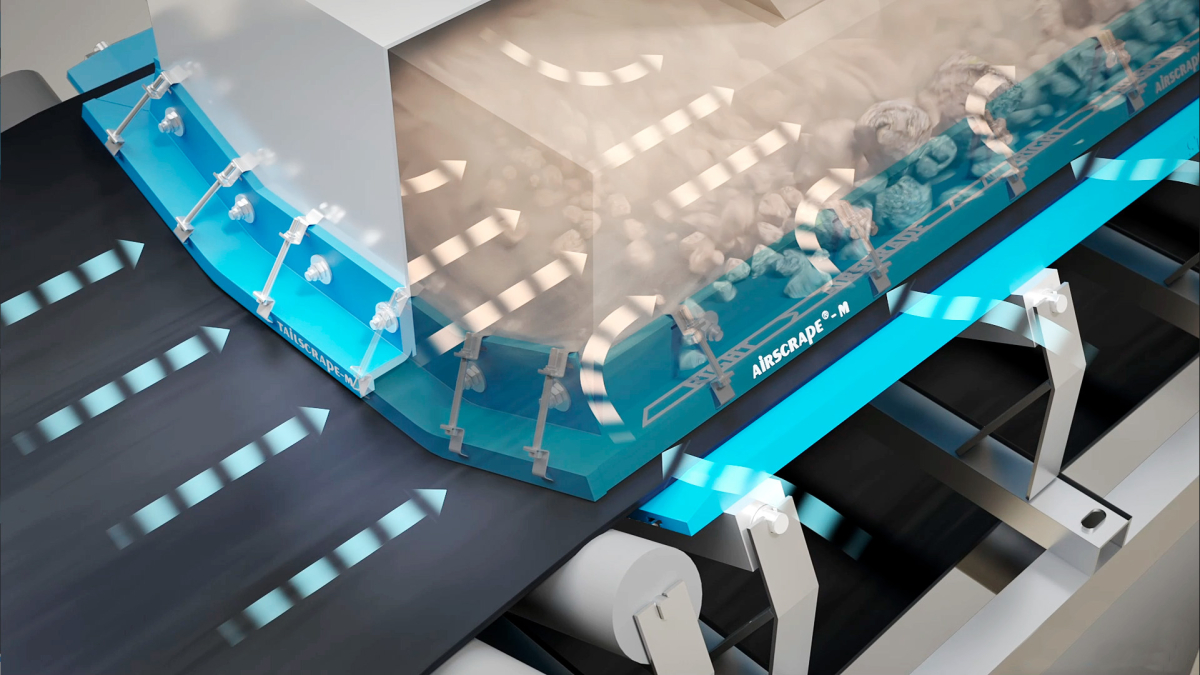

ScrapeTec products – which are engineered in Germany to pristine quality and environmental standards – are proving to offer even greater operational cost savings in materials handling, than anticipated at the launch of the range. Apart from the benefit of cost savings, the dust suppression system AirScrape is highly effective in minimising exposure of workers to environmental pollution, which is a major problem caused by fugitive dust in dry bulk handling.

Although conventional dust prevention side-seals do reduce conveyor problems in the short-term, these components quickly deteriorate as a result of friction and can also damage the belt of the conveyor during extended periods of use. The contact-free AirScrape conveyor belt skirting system is a highly-effective side seal that lies over the conveyor belt, without contact, and creates negative pressure on the belt, due to its specially-designed blade structure. Because this system hovers freely above the conveyor belt, skirt friction and belt damage are eliminated and service life of every component of the conveyor is extended.

2 AirScrape in operation

2 AirScrape in operation

© ScrapeTec

Conventional skirting is pressed against a conveyor belt to keep dust and material in the middle of the belt, but after a period, wear of the skirting and belt can be so severe, that material and dust escapes. Material spillage at transfer points needs to be removed and regular maintenance of belt skirting and transfer points is necessary. Studies show that even five years after installation and with continuous use in harsh conditions, the AirScrape system shows hardly any signs of wear. This durable system consists of non-flammable and anti-static polyurethane materials and blades made from Stainless Steel. FDA-approved materials are also available for specific conveyor handling applications.