Scrapetec-Trading GmbH

Downtimes, cleaning costs, maintenance, material wear or health hazards for employees – the cost factors surrounding the transfer points on conveyor systems are not unknown, but are usually ignored. Whether in mining, in the production of gypsum products or cement. Thanks to the co-operation with ScrapeTec, cement works in Germany have now increasingly discovered the special sustainable effect of side sealing for chutes. Manufacturer ScrapeTec International is doing a kind of persuasive work with this innovation.

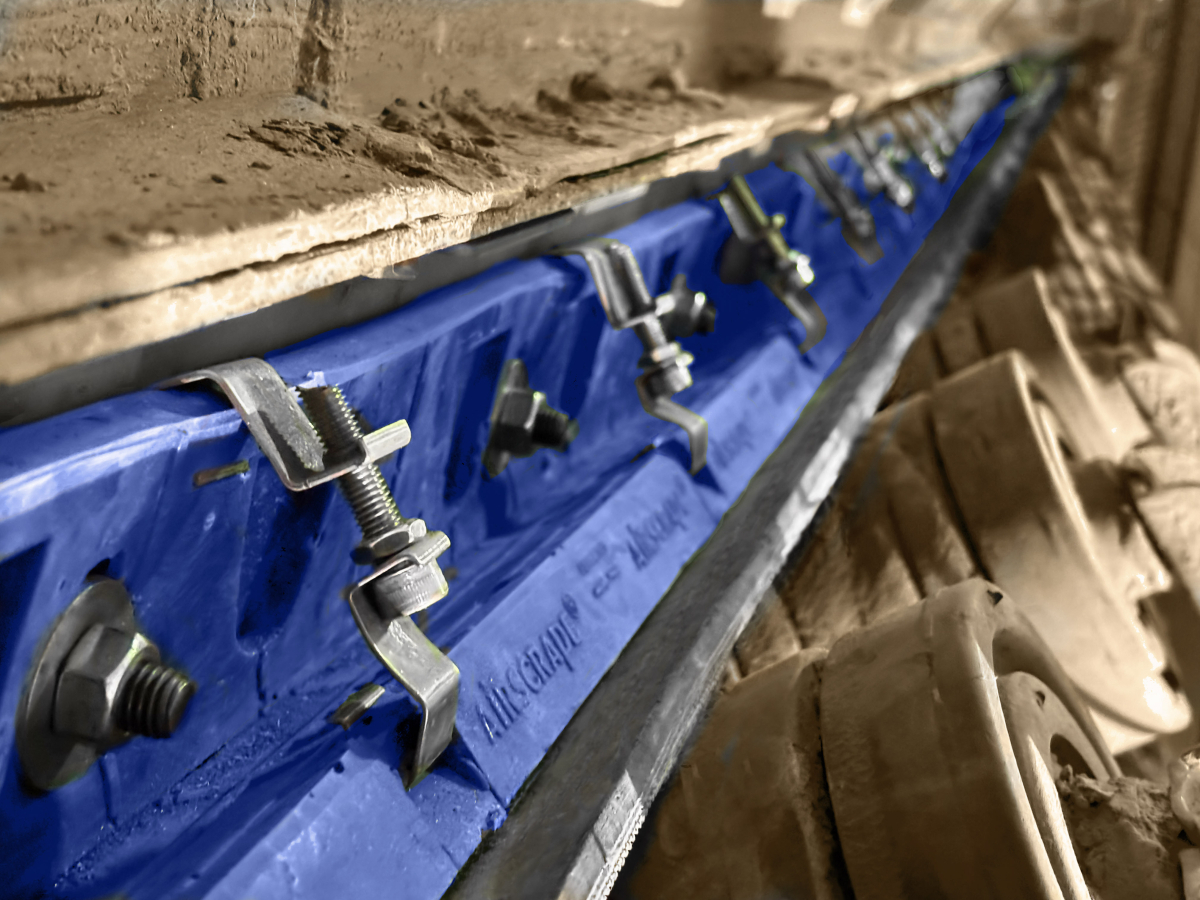

AirScrape in operation

AirScrape in operation

© ScrapeTec

Cement and gypsum plants have significant problems with dust and material loss at conveyor belt transfers. Conventional side seals are often inefficient, as friction leads to heavy wear and insufficient sealing. The non-contact AirScrape®, on the other hand, floats just above the belt without direct contact. The resulting Venturi effect guides dust and fine particles back into the material flow. In addition, the DustScrape system allows excess air to escape in a controlled manner through a special filter cloth so that the material remains in the transfer area and clean air escapes.

Immediately after installation, up to 98 % of dust emissions and material losses can be reduced. In addition, belt damage, maintenance costs and downtimes are significantly reduced. The innovative DustScrape filter system not only promises a drastic reduction in dust emissions, but also significant cost savings and improved working conditions.

The DustScrape system is characterised by its ability to almost completely eliminate dust emissions at transfer points for fine bulk materials. In closed transfer areas where high pressure can build up, the system provides effective pressure relief and prevents the formation of dust clouds.

Another notable benefit of the DustScrape system is the ability to improve the efficiency of existing active dust extraction systems. The combination with the AirScrape and the targeted air supply increases the overall efficiency by at least 50 %. This leads to further energy savings and lower maintenance costs.

Booth C2/125/1