ScrapeTec Trading GmbH

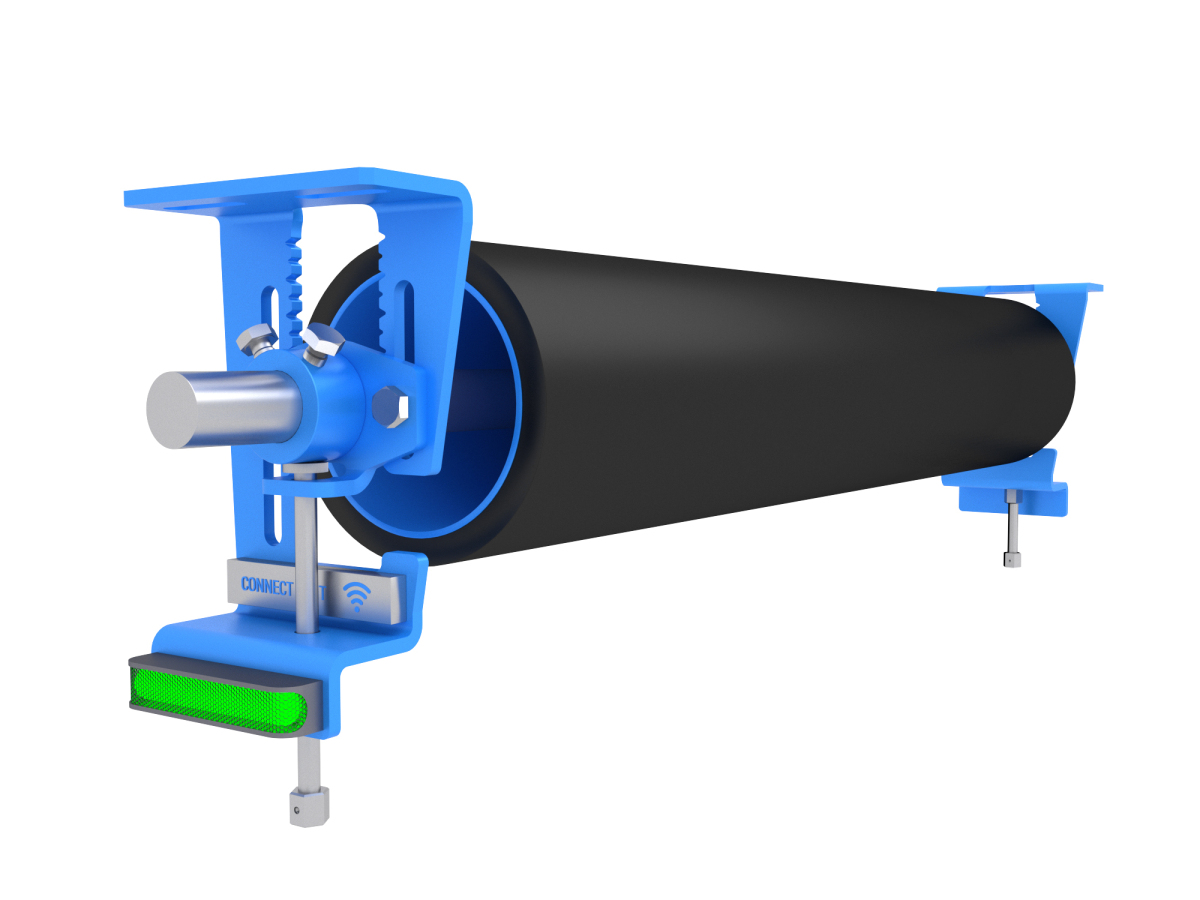

1 The conveyor tracker as the basic system of the E-PrimeTracker can be easily installed

1 The conveyor tracker as the basic system of the E-PrimeTracker can be easily installed

in existing conveyor systems

© ScrapeTec

The world premiere of this belt tracker creates the prerequisite for continuously and comprehensively recognizing and documenting the “health” of a belt conveyor in the sense of condition monitoring and predictive maintenance – with the aim of reporting irregularities and eliminating them as quickly as possible. A compact industrial computer, which is mounted directly at the conveyor belt in a robust, dust-proof and splash-proof housing, performs the data evaluation required for this.

The compact computer sends the operating data relevant to the status via mobile communications or WLAN, e.g. to a control room or to the laptop or mobile phone of the service personnel. An on-site status display, e.g. with warning or indicator lights, can also and additionally be implemented. There will also be an app that will give on-site service technicians or maintenance planners mobile “remote” access to every E-PrimeTracker at the company’s premises.

2 The E-PrimeTracker enables the integration of belt

2 The E-PrimeTracker enables the integration of belt

conveyors into predictive maintenance systems

© ScrapeTec

This transparency with regard to operating data and irregularities increases operational reliability significantly – and it reduces the risk of unplanned downtime. Wilfried Dunnwald, managing partner of ScrapeTec: “With the E-PrimeTracker, the user can continuously monitor the critical operating data of the conveyor belt and easily integrate the belt into preventive maintenance systems. Service requirements can be derived from the transmitted data because the sensors reliably detect changes and issue a warning message at an early stage – before major damage or a belt downtime occurs.” The system also collects and documents the recorded data. On the basis of this data, the user can, for example, optimize the belt’s driving style and thus extend its service life. Irrespective of this, the conveyor belt tracker continues to fulfill the task of detecting belt misalignment and automatically correcting it.

At the bauma, ScrapeTec is showing a first functional and series-ready prototype of the E-PrimeTracker. Wilfried Dunnwald: “We see this prototype and this presentation as a basis for talking to visitors about their specific requirements for condition monitoring and preventive maintenance of conveyor belts. We have many ideas on how to expand this first system – for example by integrating additional sensors, for monitoring the condition of the roller bearings, or by using artificial intelligence to evaluate the data.”

Booth C2.225/14