A revolution in conveyor belt

technology

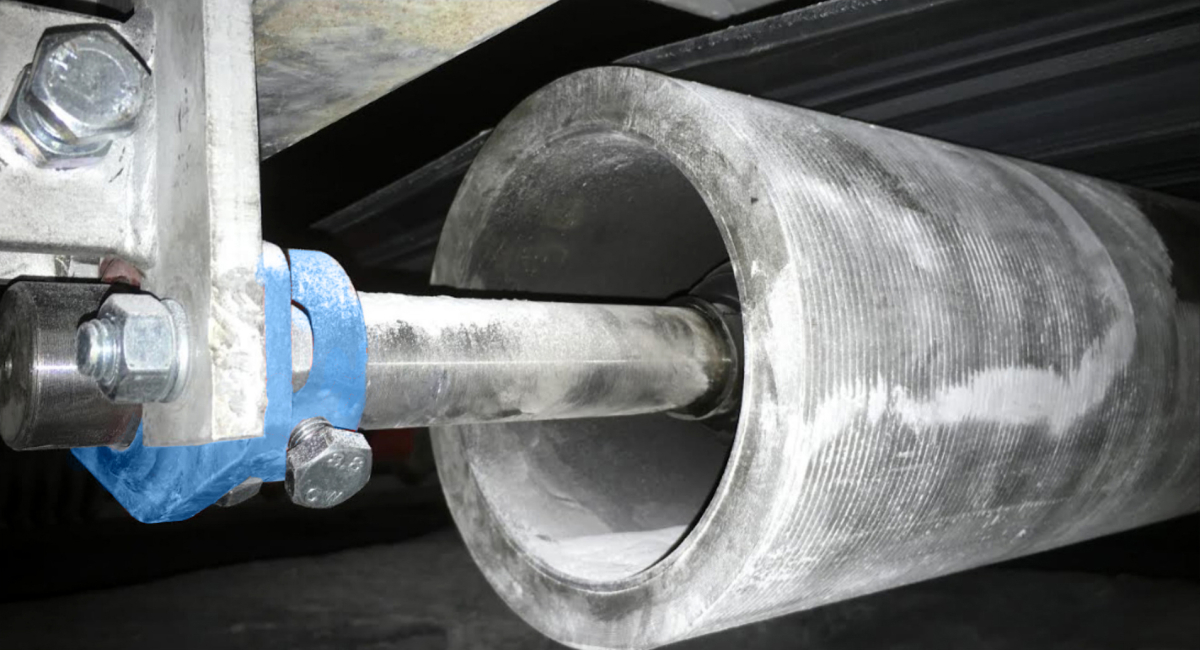

© ScrapeTec Unfortunately, it happens time and again that the belt runs off centre, which can lead to major damage. This is where the PrimeTracker from ScrapeTec comes into play – an innovative solution that ensures that conveyor belts always remain perfectly aligned. Unlike traditional trackers, which push or slide the belt into the centre due to friction, the PrimeTracker works completely smoothly and therefore offers an extremely long service life.

How the PrimeTracker works

Traditional underbelt trackers use mechanical resistance to guide the belt back to the centre. However, this causes wear and requires regular maintenance. The PrimeTracker from ScrapeTec, on the other hand, controls the belt in an innovative way. Thanks to an intelligent design, it reacts immediately to deviations and returns the belt to the centre without friction. This not only reduces wear, but also significantly extends the service life of the entire system.

Word of mouth and the PrimeTracker success story

The positive experiences and feedback from plant managers and operators speak for themselves. They praise the simple installation and high effectiveness of the tracker. The excellent results and problem-free integration have quickly made the PrimeTracker well known.

2 Detail: PrimeTracker

2 Detail: PrimeTracker

© ScrapeTec

Diversity and adaptability

ScrapeTec started with a standard quality PrimeTracker. Today, the product is offered in different versions to meet specific industry requirements:

Sugar industry: Benefits from the PrimeTracker variant in FDA quality

Mining: Utilises the FRAS quality (fire-resistant and antistatic)

Fertiliser industry: relies on the stainless steel version

The PrimeTracker has now been recognised worldwide. It is used successfully in countries such as Europe, Israel, India, Kazakhstan, Peru, Chile, the USA and many other locations. The global distribution and adaptability of the PrimeTracker to different industries and requirements emphasise its importance and efficiency.

Conclusion

The PrimeTracker from ScrapeTec offers an innovative, smooth solution for centring conveyor belts. Thanks to its extremely long service life and simple installation, the PrimeTracker has proven itself in numerous industries and regions. Thanks to word of mouth and positive feedback from users, awareness and distribution are growing steadily. The PrimeTracker sets new standards in conveyor belt technology and offers a reliable solution to a key problem in many industries.

Booth 5-P24