Optimizing supply chains with wireless level measurement

Wireless measurement has helped digitalization find its way into industrial processes that could not be economically automated in the past: level measurement in mobile plastic containers situated remotely or at changing locations. Most conventional wired measurement systems were too complex and costly, forcing users to resort to visual inspections, spot checks or guesswork based on past experience, and leading to the risk of empty containers or stalled production processes.

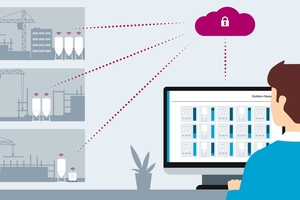

The Micropilot FWR30 finally offered a reliable and easy-to-operate measurement system for these types of applications. The battery-operated sensor requires no infrastructure in the form of power supplies or cables. The only prerequisite is adequate mobile network coverage at the container site. Robust and weather resistant, the instrument enables both mobile and outdoor operation. Installation and commissioning are uncomplicated as well. The FWR30 can be mounted on the container in just a few steps. After scanning a QR code, the system is immediately ready to operate and integrates automatically into the Netilion IIoT ecosystem from Endress+Hauser. Measurement values are sent via the cloud to mobile or stationary end-user devices at configurable intervals.

This practical IIoT solution has found numerous satisfied users who can optimize their logistics and warehouse processes, reduce costs and increase productivity. Since the actual material inventories are visible at all times, unplanned additional trips to empty containers or unnecessary material runs can be avoided, making just-in-time deliveries to the containers possible. For these applications Endress+Hauser offers specific digital services ranging from simple level monitoring to automated inventory and delivery management.

Sensor enhancements developed with users

Based on its practical experience and in close collaboration with users, Endress+Hauser has enhanced the functionality of the sensor over the past few years. One example is level measurement in metal containers. Because the Micropilot FWR30 measures through the container wall, and given that radar beams cannot penetrate metal structures, use of the instrument was originally restricted to plastic tanks and open containers. In response to the needs of various core industries, Endress+Hauser developed a new process fitting for metal tanks and silos that is screwed to a pre-mounted threaded connection, allowing the radar beams to reach inside metal containers. Apart from liquid measurements, other important innovations included level measurement for bulk solids, as well as GPS tracking, which simplifies locating the containers and facilitates usage-based route planning for deliveries.

One customer that has benefited from these innovations and actively contributed to their implementation is Profibaustoffe Austria GmbH. Among other things, the algorithms for measuring solids were improved within the framework of test installations. “We developed and implemented the optimal solution for silo level monitoring together with Endress+Hauser,” explains Christian Keitzer, deputy sales director for the Austrian manufacturer of construction materials. “The collaboration was ideal and we are highly satisfied with the result.” Optimizations were implemented on the software side as well, such as an improved map view in the SupplyCare Hosting inventory management application, which simplifies the overview of the dispersed construction material silos. Product-specific conversions can be configured in the software as well to calculate the mass within a silo.

Fields of application significantly expanded

These innovations make the Micropilot FWR30 even more universal. Apart from typical applications such as measuring the levels of liquid additives and cleaning agents in the food industry, or liquifiers in concrete manufacturing, other media such as raw construction materials, animal feedstock and wood pellets for heating systems can now be measured. For typical IIoT applications, the Micropilot FWR30 comes as a package that includes various digital services such as SupplyCare Hosting. The Netilion cloud reliably protects all of the sensor data against loss and unauthorized access.

The benefits of the Micropilot FWR30 IIoT radar sensor

at a glance

• Reliable and cost-efficient level measurement

• Ubiquitous, around-the-clock access to relevant information

• Full transparency when storing and transporting liquids and solids

• Battery-operated sensor that requires no on-site cabling

• Scalable software applications, from measurement value monitoring

to inventory management

• Certified cloud service meets highest security and data protection

requirements

• Role-based user management facilitates the integration of suppliers,

customers and partners

Author

Rainer Butsch, Produktmanager Inventory Management Solutions, Endress+Hauser Level+Pressure