Level measurement in the feed silo

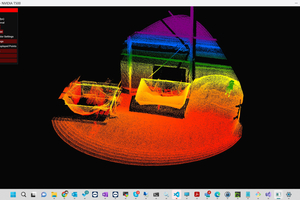

The Owl Eye® feed hopper module is a solution in the field of continuous level monitoring for feed hoppers, feed silos, conveyor belt hoppers and stockpiles. With a volume accuracy of over 98 %, this system offers a technologically advanced method of recording and analyzing the material flow in real time. A particular highlight is the integration of an industrial truck recognition system, which makes it possible to seamlessly document the movements of wheel loaders, trucks and excavators – be it when filling the bunker or unloading stockpiles. This precision in detection not only enables exact measurement of the material throughput, but also constantly provides up-to-date data on the fill level, which forms the basis for efficient operational management.

Owl Eye® – what is it anyway?

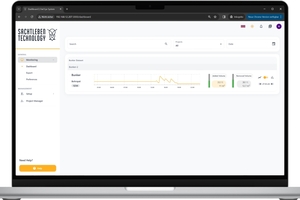

Owl Eye® is a Sachtleben Technology brand that positions itself as a central digitalisation platform for the collection of operational data. This platform is characterised by the seamless integration of a range of precise measurement tools that enable comprehensive and timely collection of critical operational data. The collected data is processed and visualised by a powerful database application and made available to users via various interfaces. Owl Eye® serves as a key resource for organisations looking for ways to improve operational transparency, increase...