Optimised XRT ore sorting solution for fine particles

Sorting small particle sizes to add value to the process

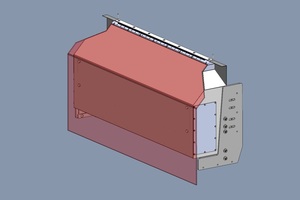

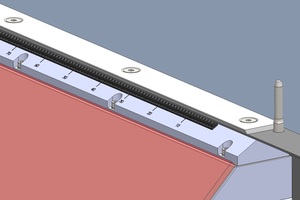

The new high resolution TS100C ejection module features a new type of ejector that is four times faster. Together with the new high performance image processing unit, it delivers higher precision in sorting small particle sizes at high throughputs. The mechanical design of the sorter has also been improved by the introduction of a new splitter plate and more precise calibration equipment to ensure the greater precision in the alignment between detection and ejection systems required for fine particles.

The fast and highly precise ejection module uses significantly less compressed air to eject the particles and reduces the energy consumption dramatically. Extensive test work was conducted at the TOMRA Test Center, both with artificial material mixtures and real-world sample material. The tests showed a spectacular reduction in air consumption compared to industry standards, as well as an improvement in product purity of around 15 %. With the consequent cut in operating costs, sorting small particle sizes down to 4 mm with the COM Tertiary XRT Fines sorter is not only viable, but adds value to the process.

“We are receiving a rapidly growing number of requests from customers to sort smaller particles,” comments Ines Hartwig, Director Product Management at TOMRA Mining. “One of the biggest drivers of cost in sensor-based sorting is the energy used for the compressed air for the ejectors. The new TS100C ejection module successfully addresses this issue and provides an effective solution to this increasing demand. It is a groundbreaking invention to create more higher-value product and reduce product loss.”

Tried and tested in industrial production

To gain field experience on the new ejection module, TOMRA partnered with a customer who has been running a COM Tertiary XRT to produce high-grade magnesite for more than two years. The sorter removes up to 50 % low-grade and waste material from the raw magnesite feed, with particle sizes ranging from 10 to 35 mm at about 20 t/h.

“After conducting the test work with the TS100C ejection module at the TOMRA Test Center, we were confident that it would be very beneficial for this customer,” explains Ines Hartwig. “We showed them the test results and outlined the benefits we expected the module to deliver. As soon as they saw the possible reduction in compressed air use and the consequent cost savings, they were very interested in doing the field trial.” The customer completed several trials, carefully documenting the energy savings and sorting efficiencies. The results were remarkable: a 70 % reduction in air consumption with an increase in product recovery with a lower mass pull to waste by producing the same product quality, and a capacity increase ranging from 20 to 30 t/h with comparable results.

The COM Tertiary XRT Fines sorter featuring the new TS100C ejection module has been installed at the TOMRA Test Center in Wedel/Germany and is ready to run tests for customers on material samples from their mines. Mining operators can view the tests online or experience them first-hand at the Test Center.