Mixing solutions to save energy, time and space

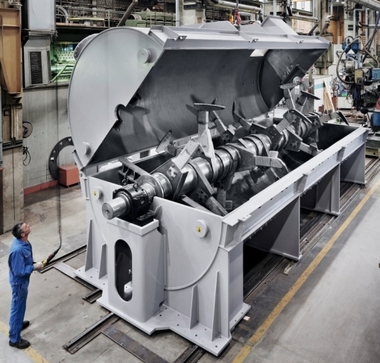

The High Efficiency Shovel, a special shovel for mixing solids in horizontal Ploughshare mixers is designed to require less drive power than a standard shovel

The High Efficiency Shovel, a special shovel for mixing solids in horizontal Ploughshare mixers is designed to require less drive power than a standard shovel

© Lödige Process Technology

The innovative shovel concept of the High Efficiency Shovel, or HES for short, immediately draws the eye. Unlike standard shovels, this in-house development by Lödige has an opening in the shovel blade. This corresponds to 85 % of the surface area. The advantage of this design: Depending on the product, it permits a reduction of the start-up torque by up to 20 % and reduces the reactive power. This makes it possible to design a mixer with a lower motor rating. The unique efficiency of this shovel also becomes apparent in its Ploughshare mixer application: The design reduces torque by approximately ten percent to save even more energy.

The HES is perfect for industries that process dry, free-flowing solids with small particle sizes. The shovel design combines high efficiency with the qualities of a standard Lödige shovel: The HES is just as easy to maintain and achieves a comparably high mixing quality.

Several process steps in one machine

In industrial production processes, chemical reactions are generally part of a multi-stage process chain comprising both the synthesis process itself and a number of processing steps before and after. Lödige vacuum mixing reactors make it possible to perform several of these steps in sequence in the same machine.

One of the most important groups of chemical reactions are solid-liquid reactions. These often require bringing the solid or solids into intensive contact with liquid reacting agents to achieve quantitative conversion in the shortest time possible. Example applications include the alkalisation of cocoa or the creation of metal soaps.

Hall 3, stand 249