One principle – many possibilities

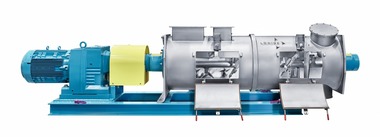

Whether bulk material, powder or pumpable mass: at POWTECH 2014 Gebrüder Lödige Maschinenbau GmbH demonstrates the versatile application of its horizontal Ploughshare® mixer. Both a batch mixer FKM and a continuous mixer KM are on display at the stand. Depending on the task in hand, the customer has a choice between various equipment options and sizes. Both machines are available with drum volumes of between 130 and 30 000 litres. A bit too big for you? At its exhibition stand Lödige is also presenting the Type N 5 laboratory mixer. With a drum volume of 5 litres it is suited to the development of products and processes, as well as small-scale production. A common feature of all models is excellent mixing quality, reproducibility and economy.

The batch and continuous mixer, as well as the laboratory mixer, all operate by the special mixing principle of the mechanically generated fluid bed developed by Lödige. The so-called Ploughshare® addles rotate close to the wall of a horizontal cylindrical drum, lifting the mixing components from the drum walls and hurling them from the material bed into the open mixing chamber. The complete product is constantly drawn into the mixing process, ensuring maximum mixing intensity.

The batch mixer FKM was designed for processing powdery, granular and fibrous bulk goods. A multitude of equipment options promote it to an all-round talent: fixtures for the addition of liquids enable the products to be moistened and granulated. Furthermore, the installation of choppers enables the processing of pumpable masses and dispersion of agglomerates. Also available: a heatable or coolable drum, front plates and shaft, as well as particularly wear-resistant materials. Short mixing times and low maintenance guarantee as high degree of operating efficiency for all mixing tasks.

Multipurpose use and efficiency due to high availability and short retention times are further features of the continuous Ploughshare® mixer KM. It is ideally suited to mixing dry, powdery, granular and fibrous solids. But with the appropriate equipment the versatile machine can also be used for processing low viscosity pastes and liquids, or for loosening agglomerates. A heatable and coolable drum, front plates and shaft are also available for the continuous Ploughshare® mixer KM. Extremely hard-wearing surfaces and high-strength steel for heavy duty operation round off the broad portfolio of equipment options.

Lödige’s Ploughshare® laboratory mixer Type N 5 with a 5-litre drum volume was specially designed for small mixing quantities in chemical and environmental technology. For example, the laboratory mixer can be used to process minerals, raw and building materials, as well as moulding and fibrous materials. The compact table model features consistently functional and ergonomic design. The control unit has been integrated into the housing. Optionally, the Type N 5 laboratory mixer can be equipped with the appropriate accessories such as a feeding funnel or a spray lid for accurate addition of liquid products.

Hall 5, Stand 222

//www.loedige.de" target="_blank" >www.loedige.de:www.loedige.de