Kleemann GmbH

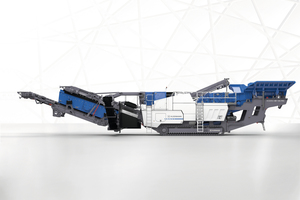

World premiere for new PRO line plant

With the impact crusher MOBIREX MR 130(i) PRO, Kleemann presents a new family member from the PRO line. The plant is used as a primary and secondary crusher and combines output, precision and sustainability. Thanks to its all-electric drive concept with the option of an external power supply and therefore CO2-free operation, the plant guarantees low energy consumption per ton of final product. The optional large double-deck secondary screening unit permits the production of two classified final grain sizes. The MR 130(i) PRO covers a very wide application range in natural stone and recycling. With its heavy rotor and powerful electric 250 kW drive, the crushing unit guarantees a very high and stable throughput. A continuous crusher load is guaranteed by the Continuous Feed System (CFS).

Operating concept SPECTIVE with new functions

The innovative operating concept SPECTIVE includes various components that are ideally tuned to one another and accompany the machine operator during the entire working day. Apart from the intuitive touch panel and different radio remote controls, the digital application SPECTIVE CONNECT, above all, supports the work site digitalisation. All relevant process information and reporting are now displayed on your smartphone without having to leave the feeding device. SPECTIVE CONNECT has new features, which will be presented at bauma and which make work for the operator even easier. A new configuration tool, for example, supports the operator in the selection of the correct machine settings.

Kleemann screening program extended

The new MOBISCREEN MSS 802(i) EVO has been designed as a powerful mobile screen for coarse elements for changing challenges in different applications. With its clever plant design and flexible conversion options, it guarantees an optimum material flow in natural stone and recycling applications. The large range of screen surfaces and simple setting of screen parameters make it possible to adapt the MSS 802(i) EVO easily to new application conditions. If a fine final product is to be screened from particularly coarse feed material, the plant can be quickly converted from three to two final grain sizes. Further advantages of the plant include its simple operability thanks to its intuitive control system, easy access to all relevant machine components and its drive concept with the option of an external power supply for emission-free and therefore environmentally sound work.

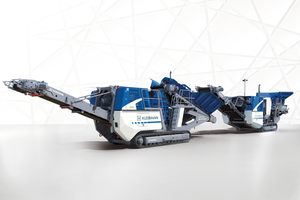

EVO2 line for flexible application possibilities

The plants in the EVO2 generation demonstrate that output, efficiency and flexibility belong together. The latest members of the product line – the jaw crusher MOBICAT MC 110(i) EVO2 and the cone crusher MOBICONE MCO 90(i) EVO2 – will be presented together to the public at bauma with line coupling. Both plants have an efficient drive concept and intelligent overload systems. Operation is simple thanks to SPECTIVE and SPECTIVE CONNECT.

The EVO2 line also includes the mobile impact crushers MOBIREX MR EVO2. The plants impress with flexible application options in natural stone and recycling. The SPECTIVE operating concept ensures simple, intuitive control. The new feature here is that SPECTIVE CONNECT is now also available.

Booth FS.1110