Hiller GmbH

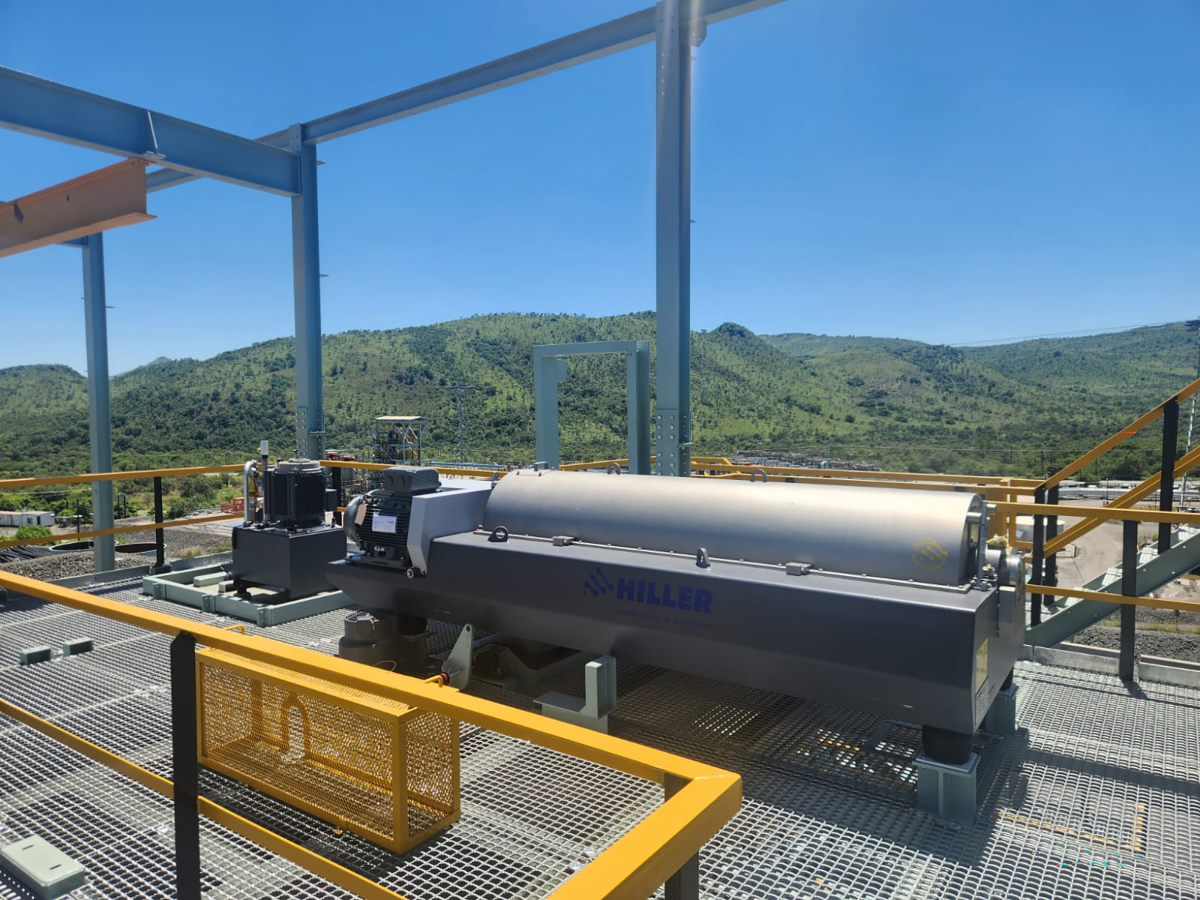

Hiller DecaPress decanter

Hiller DecaPress decanter

© Hiller

Technological excellence for sustainable success

Hiller solid bowl centrifuges stand for efficiency, operational reliability and high dewatering performance – ideal for demanding applications such as in mining. Thanks to continuous development and close dialogue with customers, Hiller has established itself as one of the leading providers of solutions that guarantee maximum efficiency and cost savings. A key factor in the company’s success is the combination of technological progress with practical innovation.

HILLER DecaPress – Optimised performance

for challenging applications

The Hiller centrifuges, specially developed for mineral tasks, offer exceptional dewatering performance, robustness and flexibility – ideal properties for handling abrasive and heavy materials.

The advantages of Hiller technology at a glance:

Highest degree of dewatering: Reduced residual moisture minimises further processing costs and increases efficiency

Robust design: Wear-resistant materials ensure a long service life, even with abrasive media

Simple operation and maintenance: Intuitive control and fully automated operation thanks to SEE-Control Pro

Low space requirement: High throughput with a small footprint

With innovative technology and practical development, Hiller is setting new standards in separation technology.

Booth C2/434