Digital service suitable for various maintenance strategies, requirements and budgets of customers

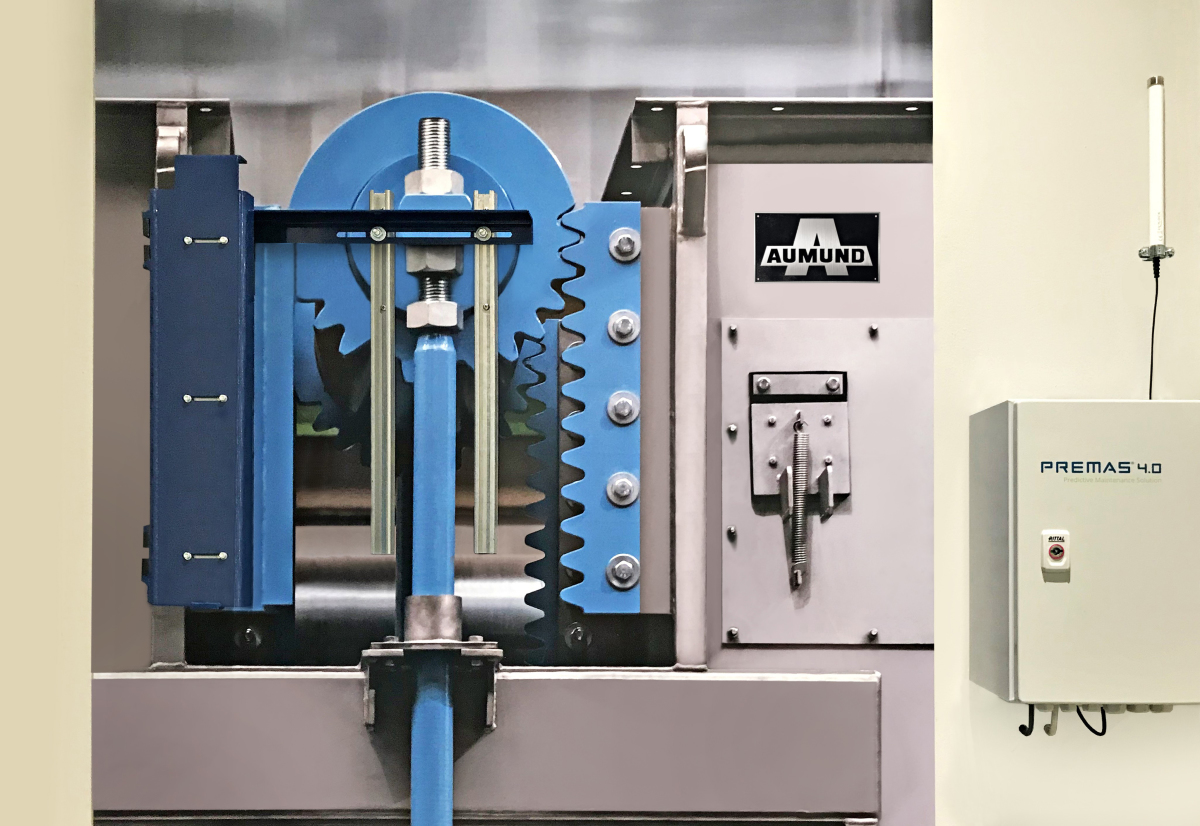

1 A display installation of PREMAS® 4.0 on a Bucket Elevator in the AUMUND Showroom in Rheinberg. The main components of the Predictive Maintenance Solution are mounted on a life-size model of a Bucket Elevator boot

1 A display installation of PREMAS® 4.0 on a Bucket Elevator in the AUMUND Showroom in Rheinberg. The main components of the Predictive Maintenance Solution are mounted on a life-size model of a Bucket Elevator boot

© AUMUND

Currently the majority of applications of the Predictive Maintenance Solution are on AUMUND machines such as Belt and Chain Bucket Elevators, Pan Conveyors and the Silo Discharge System CENTREX®. Customers of the AUMUND Group member companies SCHADE Lagertechnik and SAMSON Materials Handling also use PREMAS® 4.0 on their Stacker and Reclaimer equipment and mobile Material Feeders respectively. PREMAS® 4.0 users include concerns such as Dyckerhoff, Sabanci Holding, HeidelbergCement, Saudi Cement Company, Fujairah Cement, Union Cement, Aditya Birla Group, Shree Group, Holcim, Votorantim and Conch Cement.

Although the current focus is predominantly on cement industry customers, the PREMAS® 4.0 System is of interest to any industry with operations which depend on 24/7 reliability of conveying technology, as demonstrated by many AUMUND reference installations.

2 Test device for sensor monitoring of clamping connections on Bucket Elevators

2 Test device for sensor monitoring of clamping connections on Bucket Elevators

© AUMUND

PREMAS® 4.0 installed during conversion of the world’s highest bucket elevator

AUMUND India incorporated PREMAS® 4.0 in February 2022 into the conversion of the highest Bucket Elevator in the world, at 175.3 m, at the ACC Wadi Cement Plant (Holcim Group). Titan Cement in Greece is benefiting from the advantages of the digital system in the conversion of a Chain Bucket Elevator not originally manufactured by AUMUND. With PREMAS® 360° Maintenance Packages AUMUND USA was also successful with conversions of AUMUND Bucket Elevators for Lafarge Ravena (also Holcim) and Nevada Gold Mines, as was AUMUND Asia, Hong Kong, with Sampyo Cement in South Korea. The AUMUND Group PREMAS® 360° Maintenance Packages: Basic, Advanced and Premium are adapted to the various maintenance strategies, requirements, and budgets of customers.

Soon AUMUND will also be able to monitor the clamping connection on a Bucket Elevator with PREMAS® 4.0. Tests by development engineers at AUMUND and PREMAS have been successful, and a trial application of clamping connection monitoring is currently underway at a cement plant in Poland.

PREMAS® 4.0 – much more than just data collection

The digital service combines the latest sensor technologies with data collection and analysis, enabling early recognition of wear and ageing of important machinery components of conveying equipment. PREMAS® 4.0 gives 24/7 online information in real time about the condition of the machine, provides a forecast of the estimated remaining lifetime of critical components, and enables planning of maintenance and spare parts requirements in advance, which in turn allows action to be taken in time to prevent potential problems.

Service concept of the AUMUND Group built on two pillars

PREMAS® has been the flagship of the customer service strategy of the AUMUND Group since 2004. The purpose and objective of PREMAS® is to offer a comprehensive maintenance programme for all kinds of bulk materials handling equipment in the cement industry, in power plants, in the iron and steel industry and in many other key areas.

The service concept of the AUMUND Group is today built on two pillars, the classic in-person analogue on-site inspection of PREMAS® Preventive Maintenance Service, carried out by certified personnel, and the new predictive digital monitoring system PREMAS® 4.0 Predictive Maintenance Solution. The PREMAS® 4.0 online monitoring solution which was launched at the beginning of 2021 has already proved its viability in practice in many installations all over the world. At the same time PREMAS® 4.0 is part of the PREMAS® 360° Maintenance Packages which have been on the market since the end of July 2021.