With particle analysis on the ball

During SOLIDS 2015, trade visitors can find out about the company’s latest products at HAVER & BOECKER’s trade fair stand – which amongst others include also the new generation of HAVER EML 200 Premium test sieve shakers (Fig. 1). Walter Haver joined the management of the 1887 founded family-owned company in 1987 and, along with Florian Festge as partner, represents the fourth and fifth generation of the owner family. The particle analysis business is particularly close to his heart and W. Haver has good reason for this: “I am responsible for managing our company, wire weaving is my core business, but my great passion is the particle analysis. This was passed down to me by my forefathers.”

A chairmanship committed to high standards

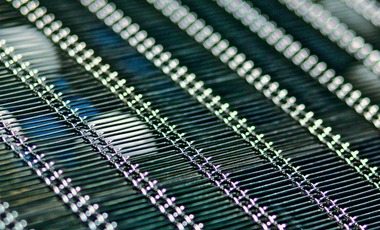

In the 1920s, W. Haver’s grandfather, Fritz Haver, was one of the first members of the TC 24 Technical Committee on Particle Analysis and Woven Wire Mesh in international standardization, the chairmanship of which he virtually handed down to his son Eitel Fritz Haver. For 30 years, Eitel Fritz Haver was involved in standardization work, and in 1990 he was awarded with the Beuth Medal by the German Institute for Standardization. Since 1999, W. Haver has been Chairman of the Committee in the third generation. He is committed not just out of passion, but primarily out of responsibility: “It is hugely important for us and for the particle analysis market that we play a part in standardization. On the one hand, these standards form the basis for all products we manufacture in the wire weaving division at HAVER & BOECKER, on the other hand the technical properties of woven wire cloths can only be described as binding in the standards. This ensures high quality standards for wire wovens, like, for example, in test sieves for particle analysis.” Striving for technical perfection and products fit for purpose, W. Haver allows himself to point out deficiencies: “Many a test sieve available on the market has unfortunately not earned its name. In some of them, the aperture size cannot be matched to any standards. The sieve frames can rarely be combined with others.”

Quality is the top priority

In his capacity as Managing Director, W. Haver is staying true to the standards he acquired as an engineer. The 63-year machine engineer specializing in manufacturing technology sets high standards for all the products that leave the factory. For this reason, HAVER & BOECKER has permanently installed bodies and processes for quality control and certification in compliance with ISO 9001: 2008. Since June 2013, the company has the first German, accredited calibration laboratory for test sieves with metal wire cloth. “In the high product quality and the innovative development lies the foundation of our business success.”

An important success factor for W. Haver is systematic orientation to the needs of the customers. “We have always conducted basic research in particle analysis. It was one of the main requirements to develop user-friendly products precisely tailored to the needs of the users. We work together with the customers to find solutions and then elaborate the results in high-quality products.” In basic research, the company cooperates continuously with universities and institutes.

W. Haver sees the company as well-equipped for the future (Fig. 2). “Over the last 15 years, the markets have developed extremely dynamically. Products and applications often used to remain unchanged for decades. Today, product cycles are no longer than 5 to 10 years. With our flexibility and the right people, in the past we have succeeded very well in meeting these challenges. I am optimistic that we will sustainably develop our companies and particle analysis in future too with creative ideas and successful products,” says W. Haver.

Hall 4 – Stand A 04