Weir Minerals announces innovative IIoT platform Synertrex®

Demand for IIoT enabled products is growing particularly in the mining industry, where it is being used in a number of areas including analytics, machine learning, and robotics. Synertrex® harnesses the latest digital technology to transform productivity, foresee risk and enhance performance. Utilising cloud computing, it involves placing smart sensors on an array of Weir Minerals products, which gather critical operating data for advanced analysis. The data is transformed into powerful insights, which are relayed to the customer through a digital interface. It can identify problems before they occur, reducing downtime, and optimise equipment performance across an entire circuit.

Remote management allows for simplified maintenance. Wear and tear can be easily monitored, and trouble spots detected before they escalate into major issues. Whether it is a drive system, structural or lubrication issues, Synertrex® provides the tools to keep mining equipment at its most profitable. Through the platform, customers will have detailed real-time insight into how their equipment is performing, and machines will be able to learn over time. Information is displayed on a simple, easy to understand dashboard, which can be accessed via any device or integrated into existing operational systems. It will convey real-time, fact-based insights into machine performance and health, remaining useful life and other crucial indicators.

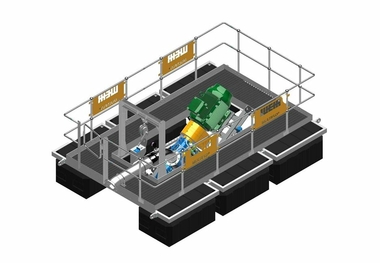

At this stage, the platform can be paired with Warman® pumps, Cavex® hydrocyclones, GEHO® PD pumps, Enduron® HPGR, Enduron® screens and Enduron® crushers; however there are plans to expand the range of compatible products. Customers with existing Weir Minerals’ products who wish to enable Synertrex® will be able to retrofit sensors to equipment.

//www.synertrex.weir" target="_blank" >www.synertrex.weir:www.synertrex.weir