WAM GmbH

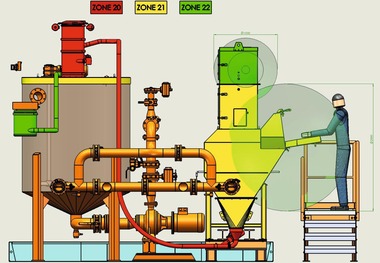

WAM is further pushing the development of its innovative filter systems. Having launched the new SILOTOP ZERO and following the extension of the ZERO series by the venting filters HOPPERTOP and HOPPERJET, the flanged round filter WAMFLO and the polygonal filter WAMAIR, all systems are now also available with antistatic filter elements. This permits the use in potentially explosive environments such as mills, sugar refineries, plastics and metal processing businesses or in paper production.

Filter systems of the ZERO series are characterized by significantly reduced dust emissions (less than 1 mg/Nm³ in cement applications) and the increase of the absorbable amount of air by 30 % compared to the previous system. With the new nano-coated filter media, it is possible to choose smaller versions of the respective filter series without compromising on capacity. Above all, plant manufacturers and operators requiring space-saving systems and high performance will benefit from this new feature. The selection of a smaller version is usually also associated with lower costs.

Existing plants with dust collecting filters containing POLYPLEAT® elements or filter cartridges can be easily adapted to ZERO filter media without problems.

WAM GmbH is exhibiting its filter systems and further components for the handling and processing of bulk materials at bauma and POWTECH.

Hall 4-257