The right mesh for screening processes

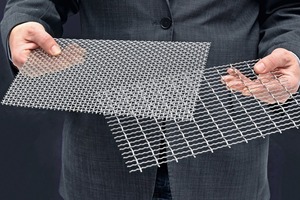

To ensure safe and efficient screening processes, material, aperture shape, weave, and screening machine must be optimally adapted to the products to be screened. The Haver & Boecker product range comprises screen media for all types of screening machines and applications (Fig. 1).

Whenever precise cut sizes for loose materials are required or whenever long particles need to be screened, it is essential to use opening mesh square. For processing coarser loose materials, the type of weaving determines the screening behaviour. Wire mesh pre-crimped on both sides, e.g. Double crimp and Lock crimp wave, causes good rotation of the screened material because of its rough three-dimensional surface. The material has much greater chances of falling through the mesh openings and thus leading to successful screening. Moreover, the fine particles are brought to the screen surface more quickly, which accelerates the entire screening process. The faster the fine particles are screened out, the more screen area is left for screening out critical incorrect size particles.

For especially heavy and abrasive materials, the upper tips of the crimped wire can wear out more quickly than the other parts of the wire mesh. This effect is eliminated by the EGLA mesh, which is smooth on one side. The flat to flat surface provides a uniform wear over the entire screen deck. However, on inclined screening machines, the smooth surface has a negative impact on screening efficiency. The material flows more quickly over the surface. Fine particles make their way to the screen surface more slowly, and all particles have less of a chance of passing through the screen. For this reason EGLA mesh should be used only on horizontal vibrating screens whenever processing difficult-to-screen materials.

When working with round or cubic type particles, a rectangular or long opening mesh is the best option. Its relatively large open screen area leads to high performance with a low tendency for clogging. If the long opening is parallel to the material flow, then a high throughput is the result. If it is perpendicular to the material flow, a more exact cut size is achieved. The greater the ratio of length to width, the more flexible the woven mesh becomes, and thus the self-cleaning effect is enhanced.

As a standard, the rectangular mesh has a side ratio of 1:3 and the same wire diameters as the square opening mesh. The open surface area is therefore higher when compared to square opening mesh. This results in higher throughputs. However, due to the smaller surface weight, the lifetime of the screen deck is less. Here Haver & Boecker offers two special rectangular meshes as convincing solutions.

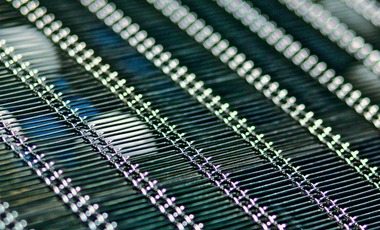

The name stands for tonnage-capacity. The woven wire is made of a fine rectangular mesh that has a width-to-length ratio of 1:6 to 1:15 (Fig. 2). This very slender mesh form allows the use of larger wire diameters when compared to square opening mesh. While the open area is about the same, the surface weight is more than twice as high. Therefore the TON-CAP mesh has a significantly longer lifetime with a similar throughput. TON-CAP mesh is especially suitable primarily for abrasive materials when a long lifetime is sought.

In addition to high surface weight, the EGLA-MAX mesh has extreme mesh proportions of up to 1:50 and has large open areas. As opposed to square opening mesh, the rectangular mesh only has a slightly greater wire diameter. Significantly larger wire diameters are used when the specifications are fine. The surface weight, and thus the wear properties, of the EGLA-MAX and the TON-CAP are similar or improved. To ensure a good connection between the weft and warp wires and to improve the stability of the screen deck, several weft wires are woven in. Thanks to the large open area, the screening machine’s throughput and capacity is increased. The extremely long opening practically eliminates jammed particles. The smooth surface on one side of the EGLA-MAX also assures uniform wear over the entire screen surface.