Sample splitter as the basis for good analysis

Over the past years the technology in the field of analytics has developed further and become more refined. The improved analysis process quickly reached its limits when it came to evaluating larger materials quantities through small test samples. Faulty sample taking can lead to serious deviations. With regards to the work that is involved in analyses, it is sometimes astonishing how little attention gets paid to test sample taking.

As a rule the amount of material taken for an analysis is much too large. A partial amount is used as a representative test sample for the total amount. To do this there are a number ways to take test samples. The extracted sample is, however, much too big for the actual analysis. Thus it is necessary to split up the sample until a representative partial amount is reached. The classic method is the complete splitting of the material amount by quartering the original amount, whereby 2 quarters of the original amount are removed. The remainder then gets remixed and quartering is repeated until the right amount remains.

This process, however, is very time-consuming and involves much effort. The process has long since been simplified by sample splitters. One device that has proven itself is the furrowed sample splitter whereby the original material amount is split up by furrows that are arranged closely to each other and the material is fed into two different receiver bowls. Half is removed and the other half is once again put through the same process and divided up until the right amount is reached. Here HAVER & BOECKER offers different sized sample splitters. Choosing the right size splitter should be done to match the maximum particle size in the material sample. Every particle needs to have the possibility of passing through a splitter opening. For larger sample sizes there is also the so-called sample reducer, whereby the sample is divided up into a fraction of the original amount. One example is the Tyler RX-18 sample splitter which reduces the sample amount to 1/16 in a single step.

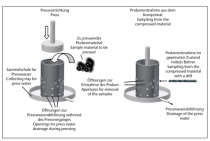

For some applications a considerably more precise sample splitting is required. Just as the taking of a sample can be faulty, so can the analysis, which then can act to propagate the error. For a test sample, it is essential that the representative composition remains the same as the base amount. Therefore de-mixing needs to be avoided. With the HAVER Rotation Sample Splitter, a process has been developed that allows a very precise test sample splitting (Fig.). Here the sample may be completely split up into small partial samples that subsequently can be further reduced. This process allows the achievement of completely uniform sample distributions, which are essential for obtaining retained samples. Because multiple, completely homogenous samples with regards to composition are attained, various analyses can then be carried out simultaneously. The result: a considerable time-saving in the laboratory.

Not every rotation sample splitter functions using the same principle. With some manufacturers the material is divided over various rotating containers, which can lead to a large scatter in the material composition, e.g. when the batch shows alternations between fine and coarse particle groups. This can lead to fine material in some partial samples and coarse materials in the others. This is avoidable using the HAVER Rotation Sample Splitter. The dosing fixture of the feeding furrows enables a precise feeding of the material flow, which discharges the particles directly over the rotating cone, accelerates them, and thus provides each particle the chance to fall through (depending on the model) one of the 30, 10 or 8 guide canals. Because of the rotational speed and design of the cone – which is according to quartering and tapering – up to 2600 splitting steps per minute are possible. De-mixing here is thus avoided. Comparision analysis of the test samples in the individual containers have shown no significant differences in particle composition.

//www.haver-partikelanalyse.com" target="_blank" >www.haver-partikelanalyse.com:www.haver-partikelanalyse.com