Rockster‘s first R1100 is still in top form

In 2009, Trummer Processing & Machinery Trading Ltd. situated in southern Styria/Austria, bought the very first impact crusher R1100, which is still running well with an optimal performance (Fig. 1). Trummer‘s primary business is the crushing contractor sector on the preparation of asphalt and construction debris. The latest project is a grand order of Asfinag. They will use about 15 % of recycled material for building a new motorway near Graz.

5 years ago Josef and Martin Trummer got in touch with Rockster for the first time and were interested in the impact crusher R900. Sales manager of Rockster, Norbert Feichtinger, promised an output capacity of asphalt with at least 150 t/h to 0-32 mm. From experience with other crushers, this performance seemed rather unrealistic, but they wanted to judge for themselves, and tested Rockster‘s R900. „But 150 t/h were even understated, because the crusher managed almost 200 t/h“, says Martin Trummer.

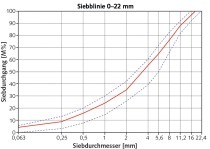

One year later Rockster launched a greater impact crusher class, the R1100, and after the good experiences with the R900, they were immediately interested in the novelty. Trummer bought the prototype and it has been in continuous use since then (Fig. 2). The machine has already processed about 4000 hours and now, 4 years later, Managing Director Martin Trummer draws positive balance. He also commends the exact grading curve of the final grain and the regular, cubic grain shape. Trummer also bookmarked: „You can always see further development of Rockster products, we constantly notice technological progress and you can see that customer requests and suggestions for improvement from experiences in the field are implemented quickly.“

At the moment Martin Trummer is thinking about investing in the latest innovation from Rockster, the parallel hybrid impact crusher R1100DE. Significantly lower fuel consumption and increased performance, confirmed of the French customer, who has the machine in use for 4 months now, are certainly good arguments. Trummer also addresses explicitly the double functional return or stockpile conveyor. “It can swivel to each side and doesn‘t need to be dismantled for transport, therefore it‘s much more flexible.“