Record-breaking processing with innovative technology

In 2009, TRUMMER Aufbereitungs GmbH, a company based in Hof near Straden not far from the Slovenian border, processed more than 850 000 t recycling material and aggregate with the help of its modern fleet of machines and experienced crew. The Rockster R1100 impact crusher bought in autumn 2009 perfectly complements the existing range of machines, enabling the company to take on even bigger jobs than before.

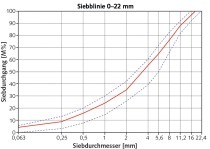

Josef and Martin TRUMMER were already acquainted with the Rockster brand even before their acquisition of the R1100. They started off with a 25-t R900 impact crusher, which – in combination with RS83 screening box – has proven a valuable addition to the TRUMMER fleet of machines. This combination of machines has been used, for instance, for the production of railway ballast, an application requiring maximized compactibility and therefore high-grade product particles with a cubic shape. When the company decided to invest in a larger impact crusher, swayed by its good experience with the R900, it opted for the next machine size up, a 32-t crusher. The concept of the impact crusher, which was bought complete with screening box, is practically identical to that of the R900. But the R1100 guarantees an even higher crushing rate. Like the R900, the R1100 is used primarily by TRUMMER for crushing asphalt (Fig.). In combination with the screening box and the oversize return belt, it is even possible to produce 100 % defined material with 0 % oversize.

Kormann Rockster Recycler GmbH, Ennsdorf (A), Tel.: +43 7223-81-000, www.rockster.at und/and www.trummer.de