Robust and mobile

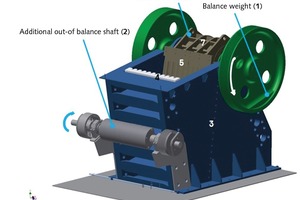

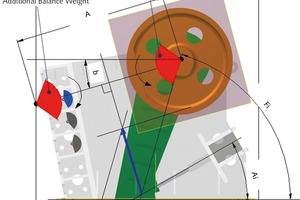

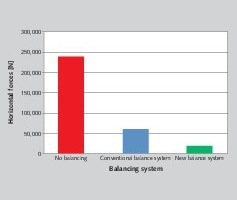

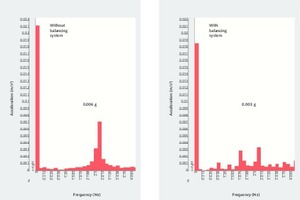

New low-vibration jaw crusher increases performance of crushing plantsSummary: Crushing plants are used in size reduction and material processing around the world. Both in stationary and in mobile either semi-mobile plants, crushers are installed on tall steel structures. These have to withstand not just the static weight loads of the crusher but also dynamic crushing loads and out-of-balance loads. In particular the cyclic out-of-balance loads can lead to fatigue and excite resonance in the steel structure. To reduce the loads on the surrounding structure, increase the performance of crushing plants and save costs, engineers at thyssenkrupp have developed a new low-vibration jaw crusher. It features an innovative balancing technology that largely eliminates out-of-balance and minimizes operating vibrations particularly in the case of installation in a steel building or in semi-mobile and fully mobile crushing plants.

Motivation

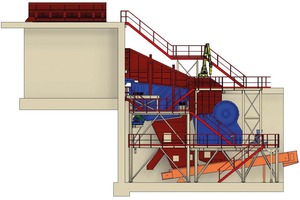

In the past crushers were often installed on massive concrete foundations stretching in some cases over several floors to absorb and dampen vibrations and machine loads. To install crushers in semi-mobile and mobile plants, massive steel structures were needed. These structures had to be extensively tested for natural resonances. If the natural frequencies were the same as the frequency of the out-of-balance vibrations of the machine, there was a risk of the steel structure collapsing. In such cases the speed of the machine had to be shifted or the stiffness/mass of the steel...