RecyclingAKTIV: recycling of construction materials

Gentle asphalt processing

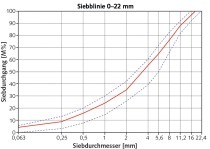

The RSS 120-M asphalt shredder from Amman processes asphalt without a significant loss of quality. The machine is built around a shredder that can recycle milled asphalt and broken lumps of asphalt without major declines in quality compared to the original material. That is because the twin-shaft shredder leaves the grains virtually untouched, with the recycled asphalt having only a slightly higher proportion of fine-grain material than the original material.

Mobile crusher systems for recycling construction material

Partner companies BMD-Baumaschinendienst and Schwab will showcase their new RA 900T recycling system in Karlsruhe. It is the largest tracked jaw crusher in the 24-tonne class and features a dual power system. The crusher for stone and rubble is perfect for transportation on a 3-axle low-loader trailer. Its simple touchscreen control, error diagnosis system and digital maintenance protocol memory ensure continued effectiveness. Alongside this, BMD will present its RA 700/7 for crushing rock and old construction material. Its dimensions, overall weight and weight distribution are coordinated so that it can be easily transported on a 3-axle roll-off tipper.

Moerschen, together with its partner Bau Süddeutsche Baumaschinen Handel, will present products like the compact Moerschen crush-bear J-750 jaw crusher. Terex Finlay will present the updated version of its J-1160 jaw crusher, along with powerful conveyor systems.

The brand-new SBM Remax 200 from Kurz Aufbereitungsanlagen packs more power in a more compact package, and will be in action at RecyclingAKTIV. This compact, electrically driven impact mill weighs 23 tonnes and has an infeed of one metre. It features a discharge chute and a top-mounted motor. Kurz will also showcase the Anaconda DF410 screening machine and its modified, twin-shaft Arjes 250 Evo double jaw breaker, with its redesigned shafts and quick-change system.

Making recycling easy with screens

Rising landfill costs are leading to a rethink when it comes to rubble. Screening systems allow users to process and largely re-use the rubble and natural products that arise during construction on site, helping to save costs. The new LS24 screening system from Xava Recycling can be fed with a compact loader weighing up to four tonnes and is ideal for processing soil, compost or gravel.

BHS Innovationen will present its recycling screens for construction materials at the demonstration trade fairs. Based in Dresden, the company focuses on keeping things simple. Its machines do not feature any hydraulics, conveyor belts or tracks. At a time when qualified staff are hard to come by, BHS machines are designed for ease of use and a long service life. While the SBR 2 is mainly aimed at recycling businesses using wheeled loaders with a shovel volume of around four cubic metres, the SBR 3 is designed for those with around one cubic metre.

The SB screening bucket from Skancraft can be used to both collect material like rubble and separate it into fine, loose and coarse components. The separator is also suitable for processing soil. It can separate and loosen wet, heavy and cohesive soils. The screening range can be adjusted for very sandy soils (grain size 0 – 15 mm) all the way to use in soil stabilisation (grain size 0 – 70 mm).

RecyclingAKTIV – demonstration trade fair for waste removal and recycling

TiefbauLIVE – demonstration trade fair for road construction and civil engineering

Between 5 and 7 September 2019, the recycling and civil engineering sector will come together at Karlsruhe Trade Fair Centre, which will be presenting the trade fair pairing RecyclingAKTIV and TiefbauLIVE for the second time. In the well-lit trade fair halls and on 80 000-plus square metres of open-air exhibition area, more than 220 exhibitors will be showcasing their latest machinery and equipment in all areas associated with recycling valuable materials and the entire range of civil engineering machines, particularly those used in road and path construction and canalisation. In the open-air exhibition area, exhibitors demonstrate their machines in action – either at their own stand or on one of the four special theme areas: Mobile Scrap & Metal Yard, Wood & Biomass and the demonstration building sites for road and path construction and for canalisation. Located right beside the open air exhibition area, the air-conditioned halls offer another opportunity for exhibitors to present themselves to their target groups in a highly professional light.

Date: 5 to 7 September 2019

Location: Karlsruhe Trade Fair Centre (open-air exhibition area and hall space)

Special theme areas: Mobile Scrap & Metal Yard, Wood & Biomass, demonstration building sites for road and path construction and canalisation

Organiser: Karlsruher Messe- und Kongress GmbH

Cooperation partner: Geoplan GmbH

Supporting civil engineering association: VDBUM

Supporting recycling associations: bvse, BDSV, BRB, DA, iste, kiwi Oberrhein, QRB, VDMA, VDM