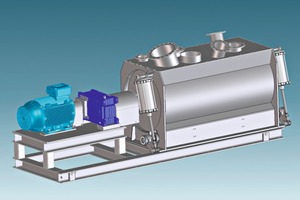

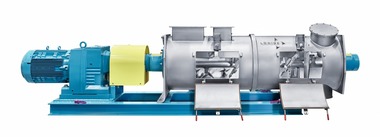

Quick, quicker, SEM

At the POWTECH 2016 the Gebr. Lödige Maschinenbau GmbH will present for the first time the quick-emptying mixer of type SEM 3000. This new development is equipped with an extra large discharge opening along the entire length of the drum. In this way the mixed product can be discharged out of the machine in seconds. This is specifically suitable for applications requiring high throughputs in combination with batch operation. Designed for the processing of solids, this model can be used in a wide variety of industrial sectors starting from the building industry to the food industry.

The large discharge opening ensures an almost residue-free discharge of the product in only two seconds. However, not only the prompt discharging sets the pace but also the quick feeding and short mixing times of the mixer. Thanks to this ingenious construction, up to 25 batches per hour can be processed. Therefore, high throughputs can be achieved in batch operation with bulk material. An efficient production is ensured even in the case of frequent change in product formulation.

The Batch Mixer operates in accordance with the principle of the mechanically generated fluid bed introduced to mixing technology by Lödige. Ploughshare® Shovels rotate as mixing elements on the mixing shaft in the horizontal, cylindrical drum of the SEM 3000. In this way, powdery, grainy and fibrous products are moved in a three-dimensional direction, whereby all of the product is constantly involved in the mixing process. This ensures high speed, precision mixing. The mixing elements are specially shaped to lift off the product away from the drum wall and to prevent particles from being crushed ensuring in this way a particularly gentle processing of the product. The mixer guarantees short mixing times at best mix quality as well as an excellent reproduceability of the batches. Designed with regard to profitability, the SEM 3000 is also characterised by a low maintenance and an easy access to all the machine parts inside. This ensures high availability of the machine for production.

The new SEM is available in four sizes with drum volumes from 1600 up to 3000 litres. As an option, the mixer can be equipped according to ATEX in case of use in a hazardous environment.

Hall 1, Stand 517

$(LEhttp://