Prognostics tool for maintenance employed in copper mine

For the extraction of natural resources all over the world, Eurasian Natural Resources Corporation (ENRC) operates different types of equipment. For management of the equipment at a copper mine in Africa, ENRC applies a digital solution characterized by innovative and efficient features. With reference to the mine in Katanga, DR Congo, it is shown how the Cassantec Prognostics software solution from Cassantec AG can be introduced to make maintenance management more effective and save on costs. First, the focus was on two cyclone pumps and the SAG mill. In a second phase, ENRC quickly extended the equipment covered, adding the ball mill, pebble crusher and belt conveyors. The recorded condition and process data for all key components of the processing plant formed the basis for the prognostics tool.

Software detects potential plant malfunctions

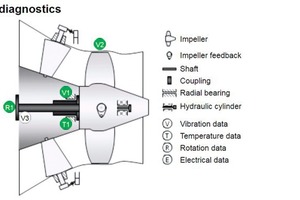

In their companies, plant managers work to maintain all processes while avoiding production losses. Unscheduled equipment downtimes make this work much more difficult. Often, repairs to components are necessary that require relatively long production outage. As a result, resources are tied up that the company could be using more sensibly elsewhere. To combat these problems, ENRC uses the Cassantec Prognostics tool. Working on the basis of plant data, for example vibration or lubricant data, the software determines probabilities for possible malfunctions in the future. Monthly updates of the data with the addition of temperature recordings provide the tool with the latest information (Fig. 1).

Vibrations exceeding limits

With the help of the prognostics software, ENRC established irregularities at the gearbox of the ball mill. Indicative of this were the vibration data exceeding the specified limits. Following closer examination, the company identified several necessary corrections to prevent potential damage. In another case, the tool detected conspicuous values for one of the cyclone pumps. As a result of this, the maintenance management was able to respond accordingly and anticipate potential failures. With selective measures implemented during already pending maintenance work, the company avoided damage to the pump without having to suffer any additional stoppages.

Saving costs with a clear and easy solution

ENRC expected from the prognostics solution extensive findings and forecasts on which to base strategic and operational decisions. With the help of the tool, flexible maintenance plans for specific parts of the plant are to be implemented efficiently. In this connection, it is essential to minimize the costs for maintaining the correct function of the equipment, without impacting its availability and reliability with the necessary maintenance measures. To meet these requirements, the software takes current and historical data, and based on this it forecasts the future condition of individual components. In this forecast, the tool takes into account typical equipment-specific malfunctions and establishes a connection to the data. From the now existing data material, Cassantec Prognostics compiles the final report, which delivers information on the condition of components and is ultimately made available on plant level in summarized form for ENRC.

Gear wheels remain intact

It is important that workflows in the copper mine are not interrupted by malfunctions. ENRC pursued this goal with the application of Cassantec Prognostics. Better adaption of the plans for corresponding maintenance measures contributes to a reduction of the costs. For that reason, ENRC is considering introducing the tool at other mines (Fig. 2) and for other components.