Avoiding loss of production by condition-based prognostic

machine breakdown means. One reason for this is a maintenance plan that is not ideally adapted to the machine. Maintenance is carried out either too early or too late – after an unplanned standstill. Failing machines can often disrupt the entire production. Probably, spare parts need to be procured. It may take days for the machines to resume normal operation. This will result in great economic damage to the company.

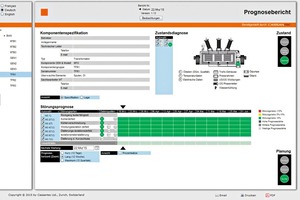

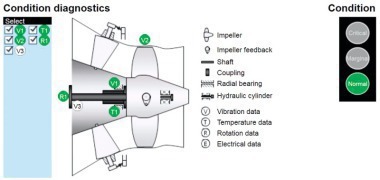

In order to avoid such machine downtimes, Cassantec offers condition-based prognostic. Using the Cassantec Prognostics method, the company elaborates a report for the individual machines and equipment, which indicates when which kind of failure is to be expected and with which probability (Fig.). From this information, the plant operator can derive the point in time at which maintenance will be required. In close cooperation with the customer, Cassantec identifies the most frequent potential faults at the individual machines. Damage history is not required, i.e. Cassantec can also prognosticate machine faults which so far have not occurred at the machine.

The company uses a combination of mathematical methods for the generation of the report. With this, future condition parameter trends, malfunction risk profiles and the remaining useful life will be determined. Using historical as well as current condition and process data, typically including thermal, vibration and lubricant analysis results, the prognostic reports can be automatically updated in periodical intervals. The results of the analysis are presented in a decision-oriented way allowing the optimization of the schedules for necessary maintenance works. Cassantec offers the Prognostic Report as a subscription service. In special cases it is possible to acquire a software license.

The plant operator will profit from this kind of prognostic solution in several areas. Cost savings are achieved by shifting from reactive or preventive maintenance cycles towards condition-based maintenance. Based on the prognostic report, maintenance decisions can be precisely justified and planned in the long term. Unnecessary maintenance operations can be avoided and in order for interventions to be minimized, they can be timely pooled. Cassantec Prognostics enables fleet-based learning.

With this, optimized maintenance schedules particularly adapted to the needs of the plant can considerably reduce maintenance costs while increasing plant availability. As a result, costs can be reduced by up to 30 %. With the respective components, such as SAG mills, cyclones or conveyor belts, the entrepreneur will save costs of up to 3.7 million € each year.

//www.cassantec.com" target="_blank" >www.cassantec.com:www.cassantec.com