Production of chippings with a new plant

In a quarry near Bad Berleburg in Germany, Middle Devonian quartzite has been extracted for the region for many decades (Fig. 1). Under the direction of Hermann Böhl, forward-looking work on the quartzite processing plant could be completed in February this year.

In December 2013, Metso Minerals (Germany) was awarded a contract to work on the design and realization of the new plant. Essentially, the machines used for processing were replaced. Some of these had been in operation for more than thirty years and their capacity, cost efficiency and service requirements no longer met operational requirements. Having concluded design and planning, Metso supplied a complete package consisting of screen, screen media and crushers (for the secondary and tertiary crushing stage). Metso also worked on the design of the new steel structure and the conveying systems, but these were actually realized and installed by the company, Steinwerk Raumland Böhl, itself (Fig. 2).

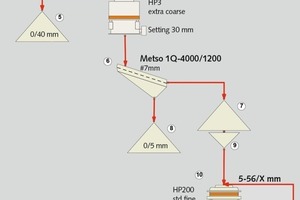

The focus of the new plant is based on the operating principle of the two new stationary cone crushers: a HP3 that crushes the feed material, which has been precrushed to 40/200 mm in a jaw crusher in the primary crushing stage, to 0/45 and 0/56 mm and a HP200 that is used as a tertiary crusher (fed by means of metering conveyors from different silos) to produce standard-size chippings 0/2, 2/5, 5/8, 8/11, 11/16 and 16/22.

For screening of the sand, a new Metso screen (Type 1Q 4000-1200) was put into operation (Fig. 3). The two crushers are centrally coordinated from the control room, each with a IC7000 advanced control system, via touchscreen terminal, in order to activate start/stop sequences, ensure continuous overload protection, monitor the temperature and crushing gap setting and make available other important diagnostic functions (Fig. 4).

The special design of the HP3 is rated highly by Hermann Böhl: “At last, we don’t get any bridging in the feed of the precrushed material to the cone crusher – the support arm of the old crusher regularly led to blockages, causing a lot of stoppages. With the new HP3 we could rule that out from the start.” The advantages of the new cone crushers are not only based on the open crushing chamber: the crusher tools are not cast in this design, so that they can be changed over in just 3 hours. The maintenance of the HP3 is much easier thanks to its design. For the purpose of dismantling, all components can be accessed from the top or the side.

Before Hermann Böhl opted for this plant, he was able to get an idea of the individual components at the German aggregate producer ProStein GmbH & Co. KG as they have been used there for a long time. Crushing tests on site with material supplied by Steinwerk Raumland Böhl provided Hermann Böhl with the necessary assurance for him to take the next steps.

Following the successful design and installation of all plant components – a process that took just six weeks (Fig. 5) – as well as a four-month start-up phase, the company owner is very satisfied today: “We’re talking about a 10 – 15-% increase in output with the same drive power requirement. There are hardly any stoppages.” The throughput rate of the HP3 secondary crusher has since reached a capacity of 260 t/h, which has now been restricted to 230 t/h. To achieve an acceptable cubic shape of the chippings, a combination of high stroke and high speed is necessary, both of which the two crushers can deliver (Fig. 6).

Hermann Böhl has concluded a 5-year service contract (EPP) with Metso and has arranged for extensive maintenance with change of replacement parts every 1000 hours. The regular condition analysis and a detailed operational report are included as part of the maintenance cycle, which will be an asset should the machines be resold at a later date. Steinwerk Raumland Böhl produces quartzite chippings primarily for road construction, e.g. for asphalt base courses. In addition, it supplies concrete aggregate, mineral blends and certified armour stone for bank reinforcement. At present Böhl is also supplying mineral mixes for surfacing work at a large wind farm in Bad Laasphe.

At the quarry in Bad Berleburg other materials are extracted in addition to quartzite. Geologically the quarry forms part of the Rhenish Massif and produces 70 000 to 80 000 t/a slate (0/200) (Fig. 7), which is processed in the nearby company-owned BERWILIT plant (Wittgensteiner Blähschiefer GmbH) to lightweight expanded shale aggregate (Fig. 8). At BERWILIT the material is sent through a 55-m-long rotary kiln in which it is first dried at temperatures between 100°C and 600°C, before undergoing actual expansion in the second section of the rotary kiln at temperatures around 1200°C. Besides being used as lightweight concrete aggregated, expanded shale is used as aggregate for lightweight refractory concretes for temperatures to 1100°C. Other applications include material for footfall sound absorption and laying screed slabs. Thanks to its high compressive strength, this material is used in bridge construction, the prefabricated element industry or prefabricated garages.

//www.metso-deutschland.de" target="_blank" >www.metso-deutschland.de:www.metso-deutschland.de