Optimum use of screens

crushing and screening process in natural stone and recycling applications can be improved. To obtain a high-quality end-product, it is important to individually adjust the screen to the application. For this purpose, several factors must be taken into consideration.

Especially in multi-stage crushing and screening processes, classifying screens are irreplaceable when it comes to obtaining exact product sizes. These are used later as standardized aggregate in asphalt or concrete production. A classifying screen can also be used as a standalone machine if, for example, a sized fraction of waste asphalt is to be added to a new asphalt formula. Compared to stationary systems, mobile solutions can therefore score points with flexibility combined with high capacity. Moreover, mobile screens are set up directly next to wherever the feed material is so that material transport can be reduced. Depending on whether a two- or three-deck screen is used, three or four sized fractions are produced. To obtain a high screening rate with minimized wear, the screening surface, screening pitch and the bed coverage must be selected appropriately.

Tips for efficient screen operation:

Selection of the screen media in line with the requirements of the application

Screen pitch: The steeper the screen pitch is, the larger the mesh size has to be as the feed material falls fast and lies on the screen deck for a relatively short time. If the material must be screened very thoroughly, a lower screen inclination is advisable. The screening rate is lower, but screening is more precise.

Bed thickness: The speed of the feeding conveyor influences the bed thickness, If the speed is too high, the material bed on the screen deck becomes thicker. As coarse material then floats over the bed surface, screening becomes less accurate and fine material can find its way into the oversize.

Important for a high screening rate and an accurately sized end-product is a well-organized material flow. For this reason, Kleemann equips its MOBISCREEN EVO installations with a generously sized feeding hopper, enabling feed by means of a wheel loader or upstream crusher. The material is transported on an extra-wide feed conveyor measuring 1200 mm to the screen box. To flexibly adjust the screen to different applications, the screening angle can be adjusted in line with requirements. In this way, high quality and throughput are achieved. At the discharge of the feed belt, an impact plate evenly distributes the material over the screening surface.

Factors for selection of the right screen media:

Type of material: natural stone or recycling

The particle shape: cubic or elongated shape

The required final grain size: determining the screen mesh sizes on the screen decks

The moisture content: with wet feed material, sticking of material to the screen media must be avoided

The screen inclination: the steeper the screen inclination, the larger the screen apertures must be relative to the required cut-point

Ratio of upper deck to lower deck: this should not be larger than 4:1 as otherwise sizing is not sufficiently thorough, and the application is less efficient. In addition, wear increases.

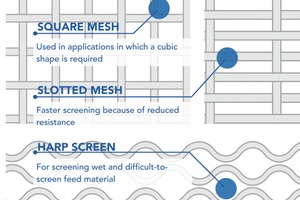

The quality of screen media is crucial for the screening performance. The higher the quality of the screen media, the more accurate is the cut-point. For this reason, Kleemann uses screening surfaces that meet high requirements for ruggedness and precision. For screening different fractions and materials, it is important to be able to rely on a wide range of screen media. The most important differences are the mesh shape – square, slotted or harp wire – and the material – steel or plastic.

Considerations for screening fine material

If the mesh size of the lower deck is too fine, the screen media can become blinded as the fine material cakes to the surface. The finer the wire is, the less caking occurs and the higher the throughput rate is. However, the wear is higher. With thicker wire, the opposite is the case. The screen media is then more rugged. Plastic screen media are well-suited for fine material and wet material as the surfaces vibrate strongly, avoiding caking. However, with these screen media, the cut-point is not as sharp as with steel screen media. In individual cases, it makes sense for the upper deck to have a coarser mesh so that the lower deck is knocked free by the coarser articles.

For screens that often process tonnes of rock in every shift, maintenance is particularly important. With MOBISCREEN EVO screens, the generously sized engine compartment facilitates inspection. Other service components are easily accessible from the all-round work platform with guard rails. Thanks to the easy access to the screen deck, changing the screen media is simpler for the operator. For example, the fine grain belt can be lowered to enable access to the lower screen media. The fast screen media change and the intuitive operation of the MS EVO make flexible adaption to new applications easy.

//www.kleemann.info" target="_blank" >www.kleemann.info:www.kleemann.info